Engineered for Excellence

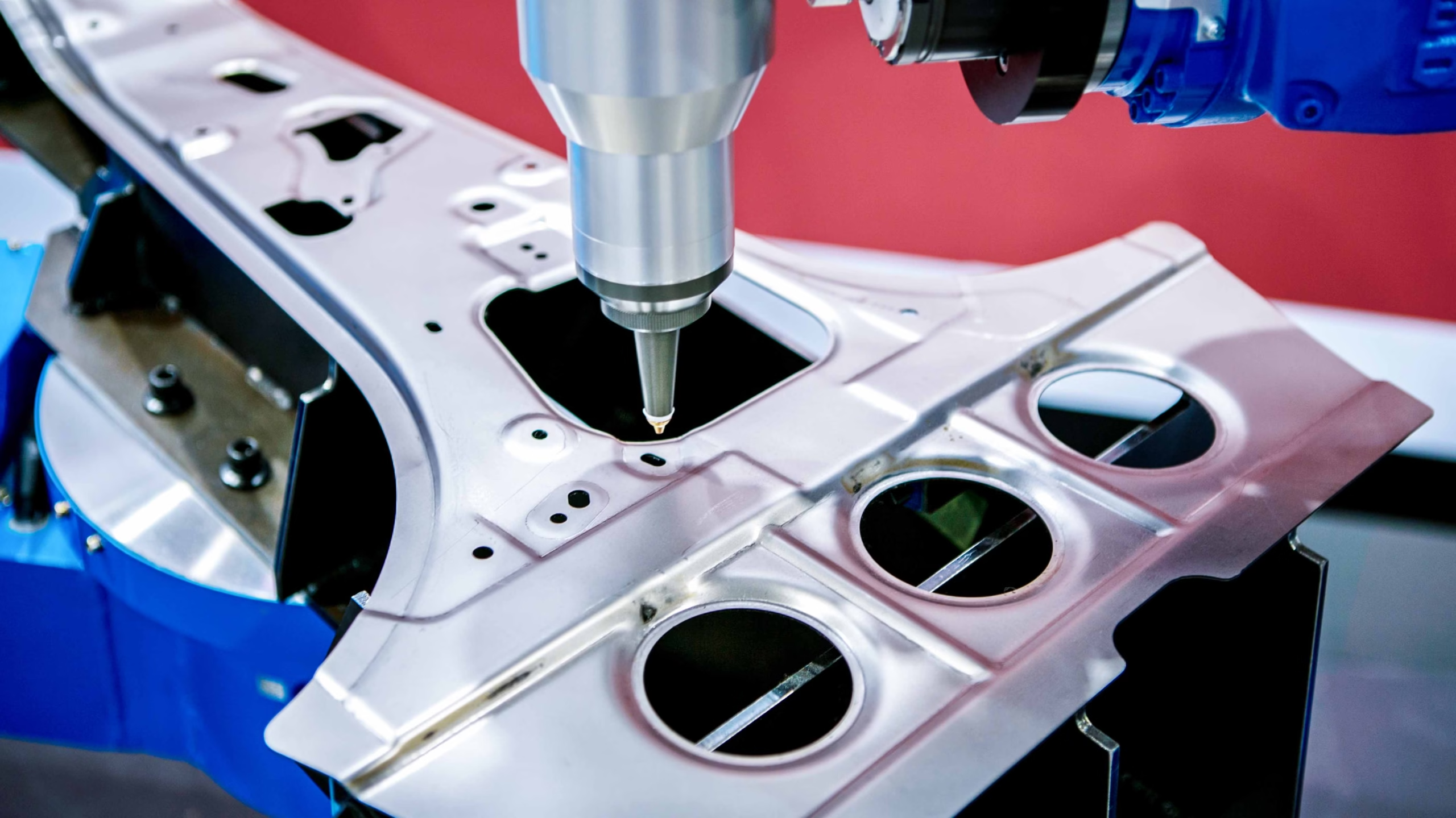

Custom Sheet Metal Fabrication

At Procision Manufacturing, we specialize in custom sheet metal fabrication services designed to meet the demands of modern product development — from one-off prototypes to full-scale production.

Backed by a commitment to excellence without compromise, our team collaborates with engineers, designers, and product innovators to deliver reliable, precision-formed components tailored to your exact specifications. With deep materials expertise, finishing versatility, and advanced CNC technology, we ensure every project is manufactured with purpose, speed, and uncompromising quality.

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Step 1

Upload Design

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Quote & DFM

Step 3

Manufacturing

Step 4

Shipping

- Total Projects

For more than 10 industries

- CNC Machines

Imported multi-axis

- CNC Materials

To choose from

- Service Satisfaction

Based on yearly surveys

What Is Sheet Metal Fabrication?

Sheet metal fabrication is one application of CNC machining that converts flat metal sheets into functional 2D and 3D components and enclosures for a wide range of industries. Using tools like CNC press brakes, lasers, rollers, and forming dies, we cut, bend, form, and weld sheet material into everything from brackets and chassis to complex housings and assemblies.

Whether you’re building a rapid prototype or scaling into production, our adaptive workflow supports custom geometries with precision, speed, and consistency.

Applications of Custom Sheet Metal Fabrication

Custom sheet metal forming is essential for industries where durability, modularity, and high performance are critical. Typical applications include:

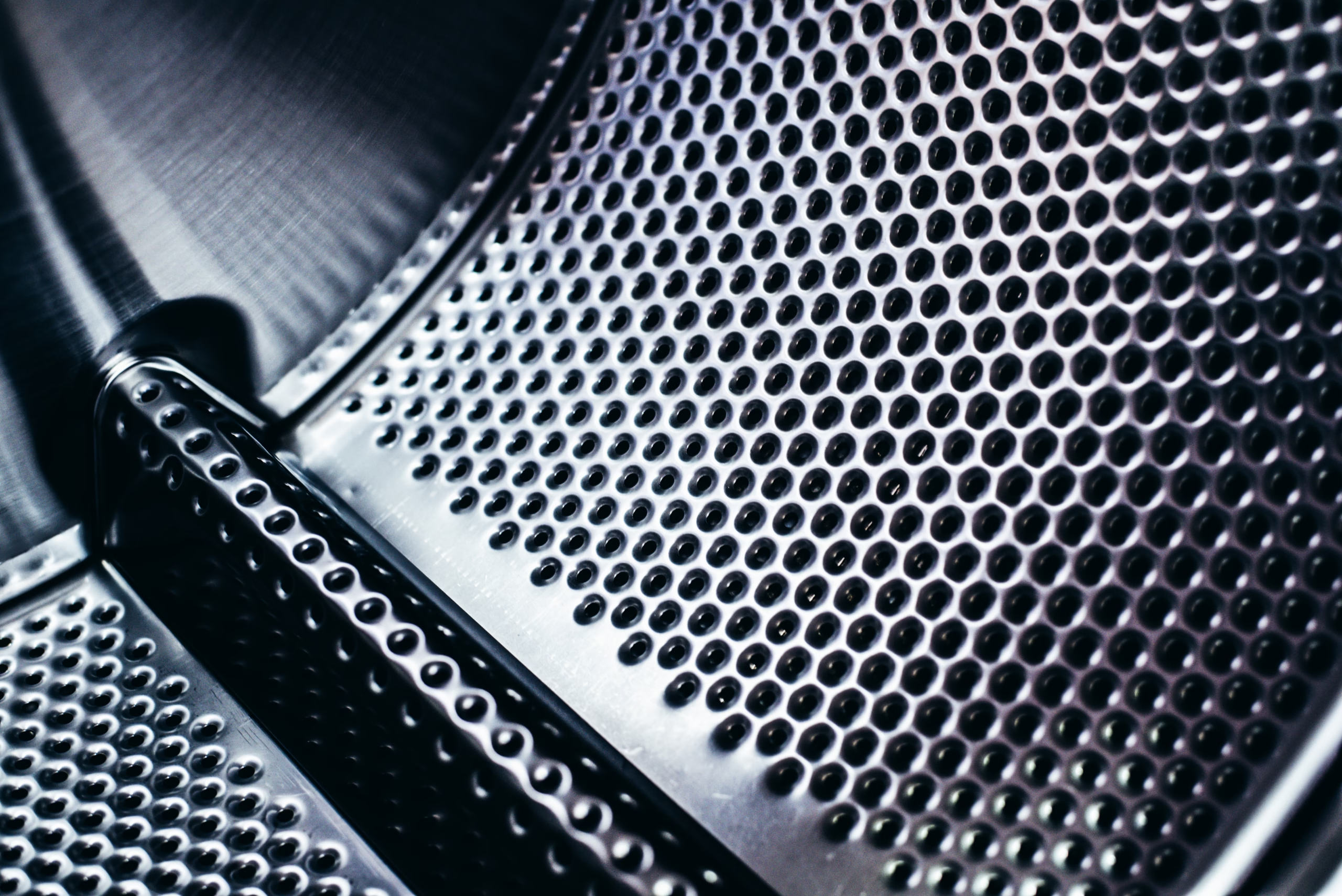

- Electronics enclosures with punched cutouts, grills, or louvres for ventilation and cable management

- Medical and robotics casings for sensors, actuators, or mounting plates

- Aerospace and automotive parts requiring lightweight yet structurally sound components

- Custom brackets, panels, and chassis for industrial and commercial machinery

Every design challenge is an opportunity to collaborate to solve, using materials and processes tailored for your application.

Procision Sheet Metal Fabrication Capabilities

We offer a comprehensive range of sheet metal services, all designed to scale with your product lifecycle.

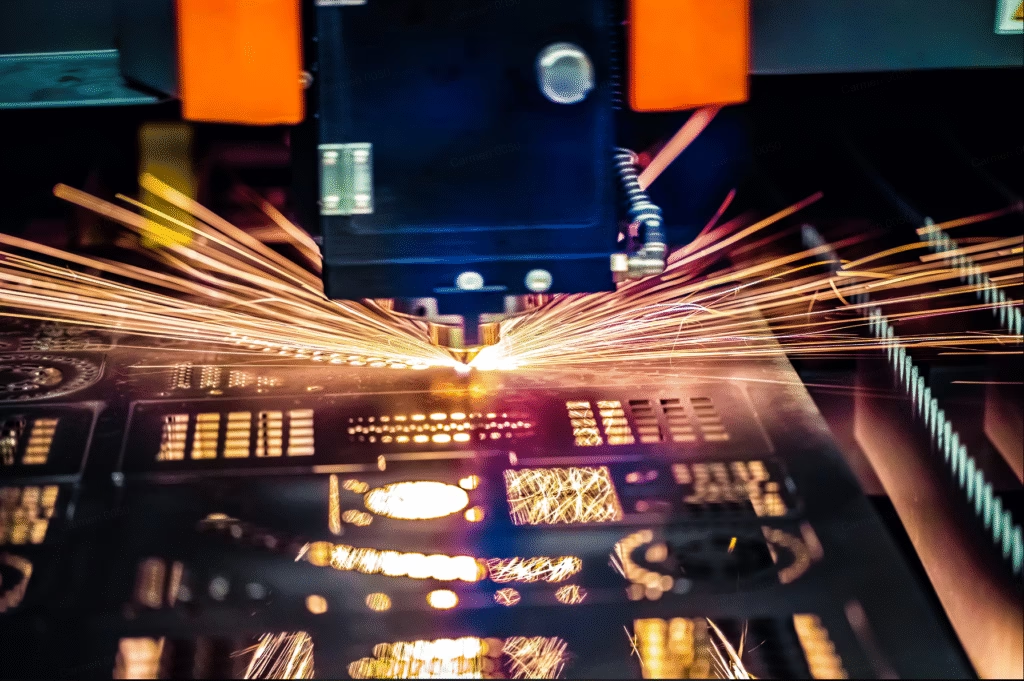

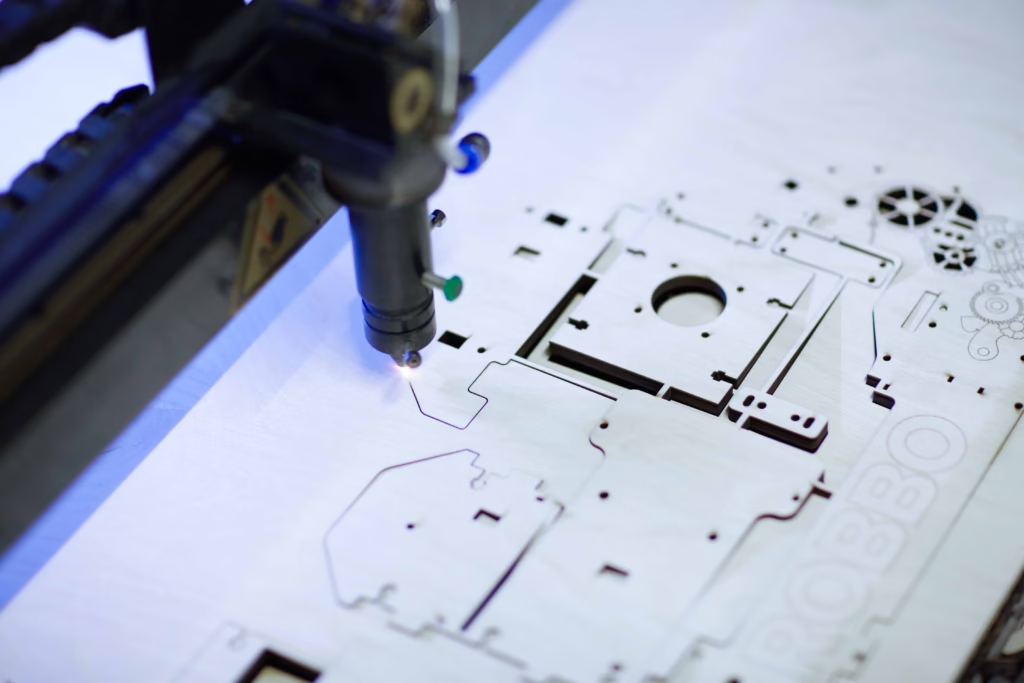

Laser Cutting

High-precision fiber laser systems cut flat stock with clean edges and micron-level accuracy — ideal for intricate patterns in materials as thin as 0.5 mm.

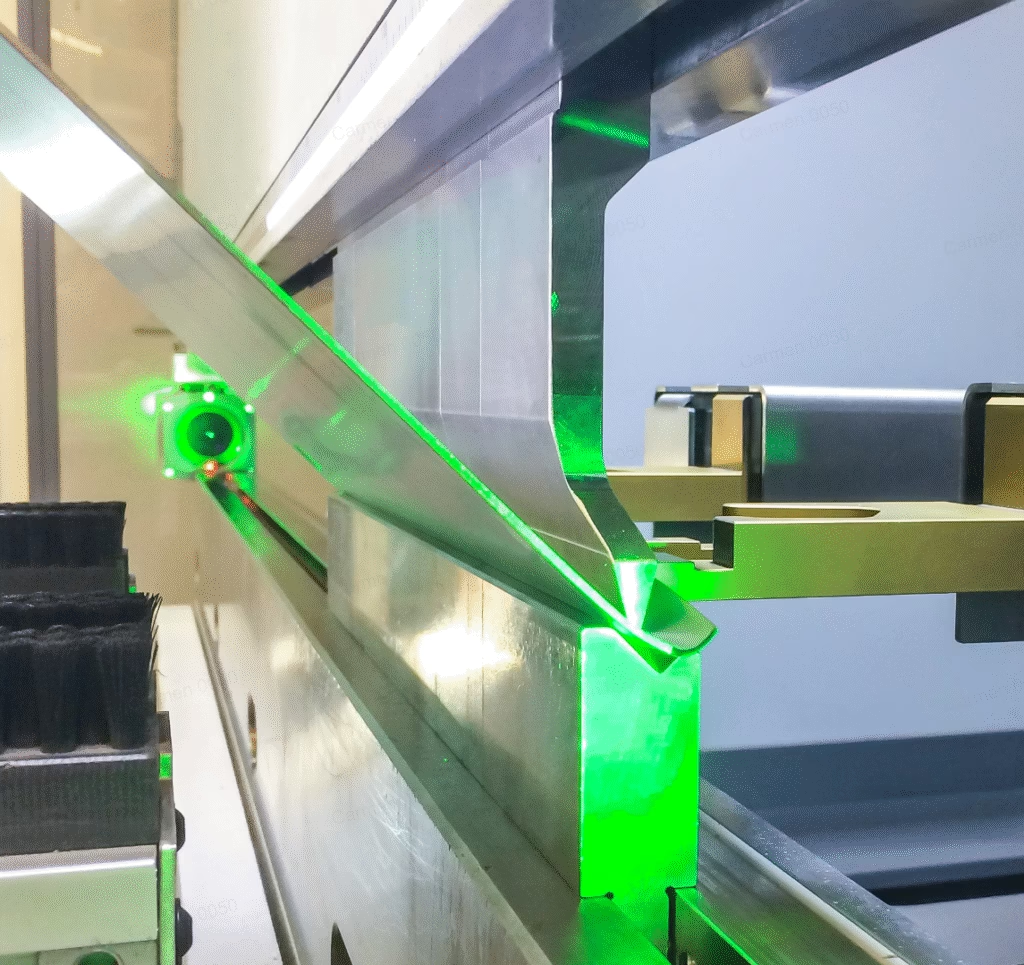

CNC Bending & Forming

We use digital press brakes and servo-driven machines for forming operations, enabling complex bends, radii, and rolled shapes in aluminum, steel, and more.

CNC Punching

Perfect for medium-to-high volume runs, our automated punch presses handle materials up to 1220 × 2440 mm, speeding up production while maintaining accuracy.

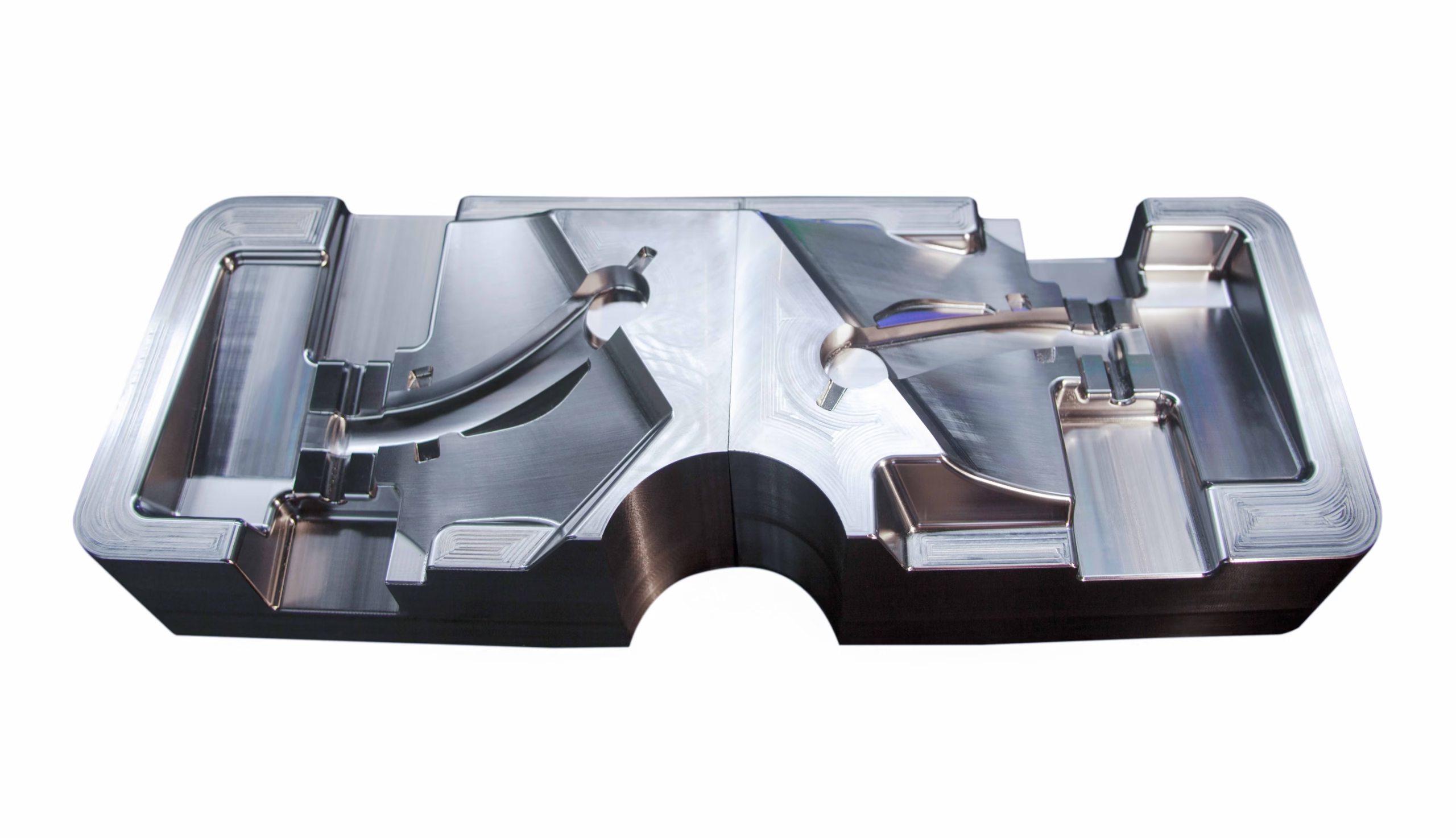

Custom Forming Dies

For complex 3D profiles and high-volume repeatability, we build custom dies to form compound curves or multi-stage features.

Precision Welding

Our welding capabilities include MIG, TIG, resistance spot, flux core, and plasma arc, with both manual and robotic stations to suit your production scope.

Drilling, Tapping & Inserts

From threaded holes, tapping holes and standoffs to blind or stepped bores, we offer full secondary machining services, including nutserts and fastener integration.

Custom Finishes

Give your parts a professional finish with:

- Priming & painting

- Electroplating & anodizing

- Laser marking

- Pad printing & silk screening

- Polishing & brushing

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

Why Choose Us?

Why Choose Procision?

At Procision, we don’t just fabricate metal — we engineer precision with purpose. Here’s what sets us apart:

Excellence Without Compromise

Every part is built to exacting standards, backed by strict quality control.

Collaborate to Solve

We work closely with your team to bring your ideas to life, from initial DFM feedback to full production.

Innovation With Purpose

Our investment in advanced CNC forming technologies ensures efficiency and repeatability at any volume.

Relentless Improvement

We continuously refine our processes and capabilities to help you get to market faster — and smarter.

Tight CNC Machining Tolerances

Production-Ready Finishes

Choose from professional painting, anodizing, media blasting, hand and machine polishing, laser etching, plating, and more — for ready-to-ship results.

Materials & Sheet Sizes

| Material | Grades Available | Thickness Range |

|---|---|---|

| Aluminum | 5052, 1100, 1050, 5083, 6061 | 0.5–10 mm |

| Mild Steel | SGCC, SECC, SPCC, SPHC, Q235, Q345 | 0.5–20 mm |

| Stainless Steel | 301, 303, 430, 316 | 0.5–10 mm |

| Copper/Brass | 1100, 2680 | 0.5–5 mm |

Maximum sheet size: 1220 mm × 2440 mm

Confidentiality You Can Count On

Common Questions

CNC Machining Service FAQs

Find answers to common questions about CNC machining services and how industries like medical, electronic, agriculture, and consumer products can achieve their goals by working with Procision.

What are CNC machining services?

CNC machining is an subtractive manufacturing,using computer-controlled tools to remove material and produce end-use parts from metal, plastic, or composites. At Procision, we specialize in precision 5 axis cnc machining, cnc milling parts, cnc turning parts, and EDM processes.

How does the CNC machining process work?

Once we receive your CAD file, our engineers will perform a comprehensive design review before generating the fastest and most efficient toolpaths for performance, speed and cost-savings.

When to use CNC machining?

Custom product developers choose CNC machining for rapid prototypes and end-use parts when they value speed, accuracy, and versatility and minimal setup costs.

CNC machining vs 3D printing?

CNC machining is typically faster and more cost-effective for metal parts. It’s ideal for tight tolerances and high-strength materials. 3D printing excels at highly complex internal geometries not machinable via traditional methods.

What materials can be machined?

Our machines support:

- Metals: Aluminum, titanium, copper, stainless steel, magnesium, Inconel

- Plastics: PEEK, PTFE, polycarbonate, acetal, and more

- Composites: Carbon fiber and specialty blends

What tolerances can you meet?

Standard tolerances are ±0.01 mm. We can support tighter tolerances as needed — just ask.

What factors affect CNC machining costs?

Cost depends on part complexity, material selection, volume, and finish requirements. Get a quote tailored to your project.

How do I get a quotation?

Upload your drawings and specifications to the Procision Manufacturing team. We will analyze all the project details and deliver an accurate quotation quickly.

Partner with Procision Today

From precision prototyping to production-ready manufacturing, we’re your partner in bringing custom sheet metal fabrication products to life. Let’s build what’s next — together.