Your Precision Manufacturing Partner

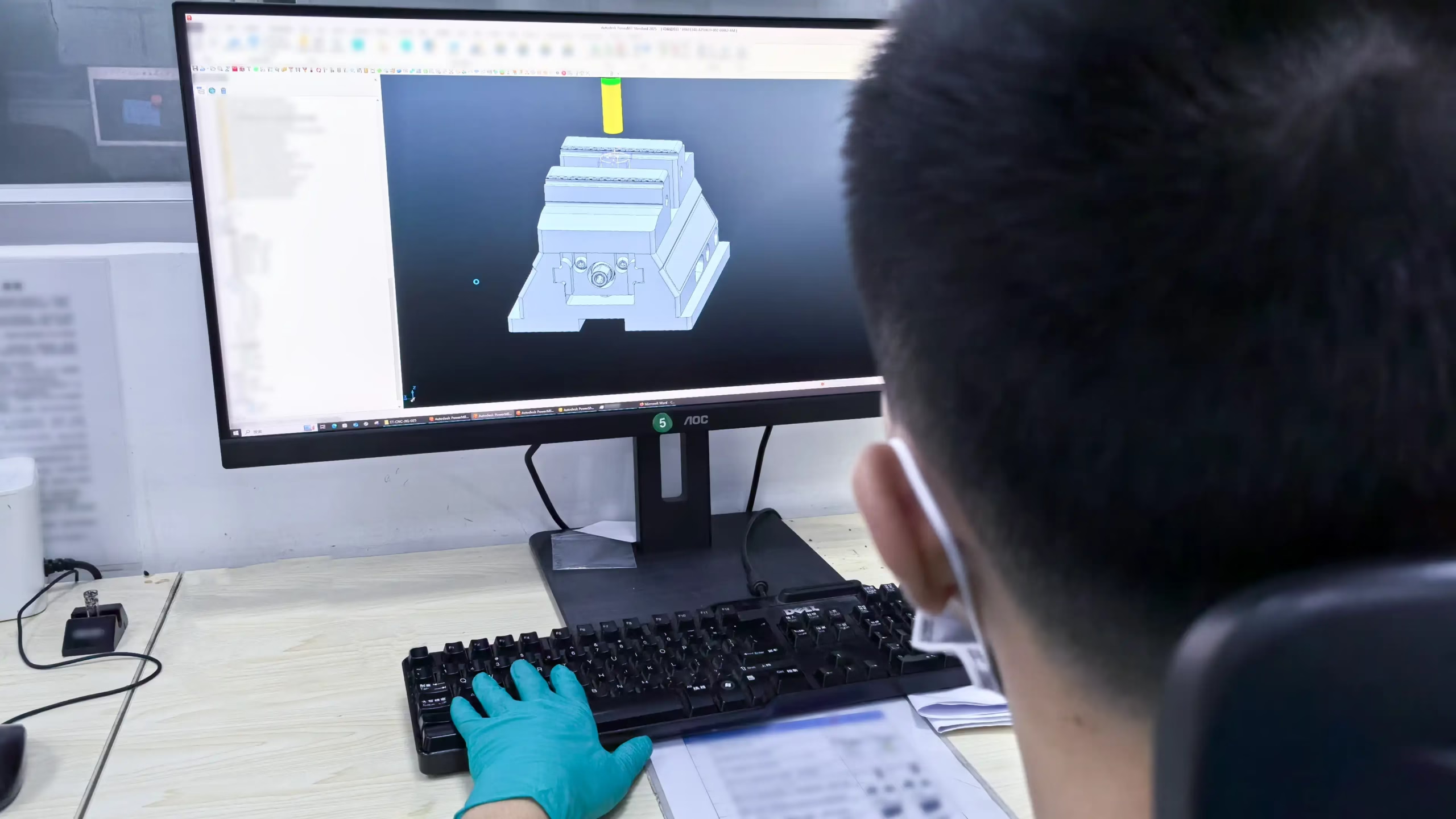

As a trusted precision manufacturing company, we leverage cutting-edge technologies to turn concepts into reality. Whether you’re scaling a prototype or optimizing a full production run, we collaborate closely with you to solve challenges, apply purposeful innovation, and drive continuous improvement.

Step 1

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Step 3

Step 4

Explore Precision Manufacturing and CNC Machining Services You Can Rely On.

Proudly delivering tailored

rapid prototyping and production services.

Who We Are

Increases of 15% this month

Over 1k clients satisfied with our recent work

At Procision, experienced specialists from across manufacturing disciplines unite with a shared mission: to deliver precision-crafted parts and seamless collaboration, from prototype manufacturing to full-scale production. Through our rapid prototyping services and transparent communication, we ensure that your expectations aren’t just met—they’re consistently exceeded. Our commitment to excellence means that every step, from concept to completion, reflects the highest standards of quality and efficiency.

| Material Name | Characteristics |

|---|---|

| 1100-H112 aluminum | Excellent corrosion resistance, very soft, and highly ductile. Weldable. Essentially all aluminum is non-magnetic. Requires very sharp cutting tools with lubricant. Potentially explosive dust. |

| 2014-T6 aluminum | Very strong, excellent fatigue resistance, but lower corrosion resistance than many other aluminums. Non-magnetic, poor weldability. Copper content can be abrasive—expect moderate tool wear. |

| 2024-T3 aluminum | Excellent strength-to-weight ratio and fatigue resistance; widely used in aerospace but with poor corrosion resistance. Good machinability, not weldable. |

| 2024-T351 aluminum | Excellent strength and fatigue resistance; widely used in aerospace structures. Very good machinability—better than many other high-strength alloys. Cuts cleanly with less tool buildup than softer aluminums. |

| 5052-H112 aluminum | Exceptional corrosion resistance (especially in marine environments) and excellent formability, but relatively low strength. Weldable. |

| 5052-H32 aluminum | Outstanding corrosion resistance (especially marine), moderate strength, very formable. Fair machinability. Similar to H112 but slightly easier to cut thanks to added strength. Still prone to gumming and built-up edge if tooling isn’t sharp. |

| 5083-H112 aluminum | Exceptional corrosion resistance in marine and chemical environments, with higher strength than 5052. One of the best weldable aluminums, especially for marine use. |

| 6060-T6 aluminum | Similar to 6063, but with slightly better strength; excellent corrosion resistance and anodizing response. Widely used in architectural and structural applications. Excellent weldability. |

| 6061-T6 aluminum | “Workhorse” alloy of the 6xxx family — good balance of strength, corrosion resistance, and machinability. Extremely common in aerospace, automotive, and general engineering. |

| 6061-T651 aluminum | Workhorse alloy like 6061-T6, but chosen when tight tolerances are needed in machined parts. Very good machinability, nearly identical to 6061-T6, but with less distortion after machining due to stress relief. |

| 6063-T6 aluminum | Sometimes called the “architectural alloy” — prized for excellent surface finish, anodizing response, and corrosion resistance, though not as strong as 6061. Weldable. |

| 6082-T6 aluminum | Strongest of the 6xxx series alloys, often seen as a European alternative to 6061. Offers excellent corrosion resistance and weldability with better strength. |

| 6082-T651 aluminum | Good machinability, weldable. Excellent general resistance, but galvanic corrosion possible if in contact with copper or steel in salty environments. |

| AL7075-T6 aluminum | Among the strongest aluminum alloys available, with strength comparable to many steels. Very common in aerospace and defense, but reduced corrosion resistance compared to 6xxx series. Poor weldability, good machinability. |

| AL7075-T651 aluminum | Similar in strength to 7075-T6, but with improved dimensional stability. Moderate to high tool wear — zinc/copper content can be abrasive; coated carbide tools recommended. |

| Material Name | Characteristics |

|---|---|

| 17-4 PH stainless steel | Excellent combination of high strength, good corrosion resistance, and heat treatability — used widely in aerospace, energy, and marine. |

| 303 stainless steel | Known as the “free-machining stainless steel” because of added sulfur (~0.15–0.35%) which breaks up chips. Offers excellent machinability at the expense of some corrosion resistance and toughness. |

| 304 stainless steel | General‑purpose austenitic stainless. Good corrosion resistance. Weldable. Work hardens. Typically non‑magnetic (may become slightly magnetic when cold‑worked). |

| 316 stainless steel | Often called “marine grade stainless” because of its superior resistance to chlorides and acidic environments compared to 304. Fair to poor machinability compared to free-machining grades (303). It is tougher, gummier, and tends to work harden quickly. |

| 316L stainless steel | Fair to poor machinability (similar to 316). The low carbon content doesn’t significantly change machinability but improves weldability. |

| 416 stainless steel | The first free-machining stainless steel, with added sulfur (~0.15%) for improved machinability. Stronger and harder than austenitic grades, but with lower corrosion resistance. Poor weldability. |

| 420 stainless steel | Can be hardened by heat treatment to the highest hardness of any stainless steel (up to ~50 HRC). Offers good wear resistance but relatively poor corrosion resistance compared to austenitic grades. Magnetic. |

| 440C stainless steel | Hardest and strongest of the 440 series (A, B, C). Difficult to machine, extreme tool wear. Poor weldability, strongly magnetic. Excellent surface finish. |

| SAF2205 stainless steel | Balanced austenitic + ferritic microstructure provides higher strength than 304/316, with excellent resistance to stress corrosion cracking, pitting, and crevice corrosion — especially in chloride environments. |

| Material Name | Characteristics |

|---|---|

| 1008 carbon steel | Very low carbon content → excellent formability and weldability, but low strength and hardness. Often used in cold-rolled form for deep drawing and forming. Strongly magnetic. |

| 1020 carbon steel | Balance of good machinability, weldability, and toughness. Stronger than 1008/1010 steels, but still easy to form and machine. Excellent weldability. |

| 1045 carbon steel (AISI 1045) | Higher strength and hardness than low-carbon steels (1008–1020). Readily heat-treatable for improved mechanical properties. Very common for shafts, gears, and wear parts. |

| 1050 carbon steel (AISI 1050) | Higher carbon than 1045, giving it greater strength and wear resistance, but reducing machinability and weldability. Can be heat treated to achieve good hardness (~50 HRC). |

| EN8 carbon steel (similar to AISI 1040/1045) | Medium‑carbon steel. High strength. Responds to heat treatment. Only fair weldability, good machininability in the unhardened state. Poor corrosion resistance, magnetic. |

| Q235 carbon steel (Chinese standard, similar to A36) | Machines and welds well, good formability. Poor corrosion resistance, tough and strong for general purpose heavy construction. |

| 1215 carbon steel | Among the best machinability of all carbon steels (~160% machinability rating vs. 1212 baseline). Poor corrosion resistance and hard to weld, used where speed and economy of machining matter more than strength. |

| 12L14 carbon steel | Excellent machinability, welding should be avoided. Surface hardening only, used for economy and speed but not strength. |

| AISI 1018 carbon steel | Excellent machinability and weldability, poor corrosion resistance. Good for case hardening on machine parts. |

| Material Name | Characteristics |

|---|---|

| 4130 alloy steel | Machines best in normalized or tempered condition with sharp carbide tooling and proper coolant. Weldable, must be coated to resist corrosion. |

| 4140 alloy steel | Fair machinability, tougher than 4130 due to higher carbon (~0.4%). Limited corrosion resistance, welding requires preheating. |

| 4340 alloy steel | Tougher to machine than 4140 due to higher nickel and hardenability. Used in heavy-duty structural parts in aerospace and defense. |

| Material Name | Characteristics |

|---|---|

| 718H tool steel | Machines cleanly with carbide tooling; slower than mild steels but better than fully hardened tool steels. Good for plastic injection mold tools. |

| A2 tool steel | Fair machinability, poor weldability. Air-hardened. Best used for cold-work tooling, punches, dies, shear blades, and forming tools. |

| M2 tool steel | Difficult to machine in the annealed state due to high alloy content. Best for punches, reamers, and cold-work tooling requiring great hardness and wear resistance. |

| NAK80 tool steel | Machines well with carbide tooling; excellent polishability for mirror finishes on plastic injection mold tools. |

| P20 tool steel | Machines well with carbide tools. Fair weldability, limited corrosion protection. Extensively used for PIM tools. |

| S136 tool steel | Excellent corrosion resistance for a tool steel — stainless composition makes it resistant to humidity, corrosive plastics, and condensation. Ideal for molds running PVC, acetate, or corrosive resins. |

| Material Name | Characteristics |

|---|---|

| T2 copper (C11000 equiv.) | Poor machinability, very gummy, tends to grab tools and produce long, stringy chips. Good corrosion resistance in atmosphere. Best for general electrical and thermal applications requiring high conductivity. |

| Material Name | Characteristics |

|---|---|

| 360 brass | Excellent machinability, benchmark free-machining brass (~100% machinability rating). Not recommended for marine or strongly corrosive environments. Used in high-volume screw-machine parts, fittings, fasteners, and valves. |

| H62 brass | Fair machinability, less free-cutting than 360 brass, produces long chips. Non-magnetic, used for plumbing fittings, decorative items, and light structural applications. |

| Material Name | Characteristics |

|---|---|

| QAL9-4 (aluminum bronze) | Difficult to machine, excellent corrosion resistance. Weldable, non-sparking. Good for marine hardware, propellers, pump and valve components. |

| Material Name | Characteristics |

|---|---|

| W70 tungsten copper | Best machined with diamond or carbide tools, EDM, or grinding. Not weldable, very high corrosion resistance. Best for electrical discharge machining (EDM) electrodes. |

| Material Name | Characteristics |

|---|---|

| C17200 beryllium copper | Fair to good machinability, better than pure copper but work-hardens quickly. Non-magnetic. Used in aerospace and oilfield tools where non-sparking properties are critical. |

| Material Name | Characteristics |

|---|---|

| Ti-6Al-4V titanium | Low thermal conductivity and tool wear are common issues when machining. Good weldability, Excellent corrosion resistance. Used in medical implants and surgical instruments. |

| Ti-6Al-4V titanium (Grade 5) | Difficult to machine. Can be welded if argon-shielded. Exceptional strength-to-weight. Aerospace: turbine blades, airframe structures, fasteners. |

| Ti-6242 titanium | Similar challenges to Ti-6Al-4V but generally harder and more abrasive to machine. High-temperature structural parts in engines and airframes. |

| Material Name | Characteristics |

|---|---|

| Zinc Zamak 3 | Good machinability with standard tooling. Poor weldability, low strength. Used for pressure die casting. |

| Material Name | Characteristics |

|---|---|

| AZ31B magnesium | Excellent machinability with lubricant. Can be welded with shielding gas. Used when weight reduction is more important than ultimate strength. |

| AZ80A-T5 magnesium | Very low density. Excellent machinability, flammable chips—use dry cutting or minimal oil and proper chip control. Susceptible to corrosion. |

| AZ91D magnesium | Good machinability. AZ91D is the most corrosion-resistant of the AZ series due to its higher aluminum content. Still requires protective coatings in harsh or marine environments. |

| Material Name | Characteristics |

|---|---|

| 718 inconel | Ni‑based superalloy. Retains strength at high temperature. Very poor machinability. Weldable, excellent corrosion resistance. Used in gas turbines, nuclear reactors, downhole oil tools. |

| 625 inconel | Similar to 718, but optimized for superior corrosion resistance and ductility across a wide range of environments. |

| Hastelloy X | Ni‑based superalloy; retains strength at high temperature; severe work‑hardening; very poor machinability; use rigid setups & sharp carbide. |

| Waspaloy | Difficult to machine, poor welding but corrosion resistance is excellent. Used in industrial applications demanding creep resistance in hot oxidizing conditions. |

| Haynes 188 | Cobalt-based alloy, hard to machine. Good weldability, excellent corrosion resistance. Used for high-temperature industrial equipment exposed to oxidizing or sulfidizing conditions. |

| Stellite 6B | Extremely hard cobalt-chromium alloy, difficult to machine. Maintains performance in seawater, acids, and chloride environments. Highly resistant to galling and cavitation erosion. |

| Tribaloy T-400 | Extremely poor machinability— among the hardest cobalt alloys to machine. Resists oxidation, chloride attack, and corrosion–erosion combinations. Particularly effective against wear in corrosive environments (e.g., seawater or chemical slurries). |

| MAR-M 509 | As a cast cobalt–nickel–chromium superalloy, MAR-M 509 is extremely difficult to machine. Poor weldability, hot corrosion resistance up to ~1,090 °C. Used for turbine vanes, blades, and combustor hardware. |

| A-286 | Fair machinability, good weldability. Good corrosion resistance, non-magnetic. Found in nuclear power reactor internals, high-temperature fasteners. |

| Incoloy 800 | Excellent oxidation and carburization resistance up to ~1,100 °C. Good resistance to many aqueous environments, but less chloride stress-corrosion cracking resistance than nickel-rich alloys like Inconel 625. |

| Hastelloy D-205 | Outstanding corrosion resistance, particularly against strong oxidizing acids such as hot concentrated sulfuric acid. Found in chemical processing and reactor vessels. |

| Material Name | Characteristics |

|---|---|

| ABS | Tough, impact-resistant, dimensionally stable, easy to machine |

| ABS-LG AF312C-NT | High impact resistance, flame retardant, high flowability |

| ABS-POLYLAC PA-757 (Beige) | High rigidity, high gloss (high reflectivity), medium impact resistance |

| ABS-FR15U-NA1000-NT | Flame retardant, UV resistant |

| ABS-DIALEC M UMG U400B-CR | Flame retardant, transparent |

| ABS-POLYLAC PA-758 (TPR) | Transparent, excellent processability |

| ABS-POLYLAC PA-765A-NT | Flame retardant, high flowability |

| ABS ELIX M203FC | Food grade, high impact resistance, high gloss, high flowability |

| ABS POLYLAC PA-757F | Food grade, high gloss |

| ABS-LG HI121H (Beige) | High impact resistance, high gloss, heat resistance |

| ABS-348 000000 NAT | High flowability |

| ABS-RTP-600 | High flowability |

| ABS-TERLURAN GP-22-NT | High surface reflectivity, high toughness, high hardness, excellent appearance, medium flowability, good colorability |

| ABS PA-709 | Low-temperature impact resistance, high impact resistance |

| ABS CYCOLAC MG47F | High impact resistance, high gloss |

| ABS LG HF380 | High impact resistance, standard, high gloss, high rigidity, general purpose |

| Material Name | Characteristics |

|---|---|

| ABS+20GF SERG2 Natural | Reinforced Flame retardant |

| Material Name | Characteristics |

|---|---|

| ABS+PC | Higher strength and heat resistance than ABS; tough and rigid |

| Material Name | Characteristics |

|---|---|

| PMMA (Acrylic) | Excellent optical clarity, rigid, scratch-resistant |

| PMMA DF22-8N | Good light transmittance, weather resistance |

| Material Name | Characteristics |

|---|---|

| PC (Polycarbonate) | High impact strength, transparent, dimensionally stable |

| PC-MAKROLON 2458-CR | Medical biocompatibility Low viscosity Easy demolding Suitable for ethylene oxide sterilization Suitable for steam sterilization |

| PC-WONDERLITE PC-110-CR | Medium viscosity |

| PC-LEXAN 940A (Transparent) | Flame retardant, medium viscosity |

| PC-LEXAN 925AU-116 (Transparent) | Flame retardant, outdoor applications, bromine-free, chlorine-free |

| PC-Makrolon2856-CR | Food grade, transparent |

| PC-943A-116-NT | Weather resistance, flame retardant, transparent, UV resistance, medium viscosity |

| PC-LEXAN 223R (Transparent) | Flame retardant, UV resistance |

| PC-LEXAN 103R (Transparent) | UV resistance, weather resistance, thick-walled, halogen-free, transparent |

| PC-MAKROLON 6557-550115 (TPR) | Flame retardant, medium viscosity |

| PC EXL9134-8T8D048 | Low-temperature resistance, easy to process, high impact resistance, weather resistance, high strength, halogen-free, flame retardant, high flowability, UV resistance |

| PC-MAKROLON 9425 000000-CR | High viscosity |

| PC-LEXAN EXL9330-BK1A068(BK) | Toughened, flame retardant, UV resistance, high impact resistance |

| PC-EXL9330-7T3A2421 Grey | Toughened, flame retardant, UV resistance |

| PC-LEXAN 3413R-131-NT | Reinforced, flame retardant |

| PC-223R-111-NT | UV resistance |

| PC-MAKROLON 2407-550115 (Transparent) | Heat resistance, low viscosity, easy demolding |

| PC-MAKROLON 2807-550115 (Transparent) | Weather resistance, UV resistance, medium viscosity |

| PC-LEXAN 945A-116 (Transparent) | Flame retardant |

| PC-TARFLON LC1500 (Transparent) | Flame retardant, high flowability, transparent |

| PC SABIC LEXAN™ EXL1433T | Low-temperature impact resistance, outdoor applications, excellent processability, high impact resistance |

| PC-LD7800 NT | Heat resistance Aging resistance Transparent |

| PC-LEXAN HF1110 (Transparent) | Heat resistance High flowability Transparent |

| PC+ABS-C1200HF-100 (Beige) | Low-temperature impact resistance High toughness High heat resistance Excellent processability Contains UV-329 |

| PC+ABS Lupoy® GN5008HF | High impact resistance Flame retardant High flowability |

| PC+ABS-CYCOLOY CX7211-111 (BG) | Excellent processability Hydrolysis resistance Halogen-free flame retardant Chlorine-free Thin-wall |

| PC+ABS FR1514 901510 BBS073 BK | Heat resistance Flame retardant |

| PC+ABS FR1514 000000 NAT | Heat resistance Flame retardant |

| PC+ABS-CYCOLOY C2950 (Beige) | High impact resistance Heat resistance Flame retardant High flowability |

| PC+ABS-CYCOLOY C6600-111-NT | Heat resistance High toughness |

| PC+ABS-FR3010 000000 (Beige) | Heat resistance Flame retardant Stress crack resistance Chemical resistance |

| PC+ABS-FR3010 901510 (Black) | Heat resistance Flame retardant Stress crack resistance Chemical resistance |

| PC+ABS-T65XF-NAT-NT | Standard High flowability |

| PC+ABS-CX7211-701-BK | Chemical resistance Thin-wall Hydrolysis resistance Halogen-free flame retardant Chlorine-free Excellent processability |

| PC+ABS-CY6310-8T6D067-WT | Bromine-free Chlorine-free Excellent processability High toughness Hydrolysis resistance |

| PC+ABS-CY6310-76701-BK | Bromine-free Chlorine-free Excellent processability High toughness Hydrolysis resistance |

| PC+ABS-WONDERLOY PC-510(Beige) | Heat resistance Flame retardant High flowability |

| PC+ABS CYCOLOY FR CX7240-701 BK | Impact resistance, flame retardant |

| PC+ABS Cycoloy CX7240U | Chemical resistance Excellent processability Hydrolysis resistance Outdoor applications Halogen-free flame retardant Chlorine-free Contains UV-329 (Octocrylene, CAS No. 3147-75-9) |

| PC+ABS CX2244ME -T717238 | Medium flowability Medium impact resistance Flame retardant Chemical resistance |

| PC+ABS-KingFa JH960 | Hydrolysis resistance Easy to electroplate Easy to spray paint Halogen-free Flame retardant High flowability Chemical resistance |

| PC+ABS-KingFa JH960-6965-GY | Hydrolysis resistance Easy to electroplate Easy to spray paint Halogen-free Flame retardant High flowability Chemical resistance |

| PC+ABS Chimei 540 | Heat resistance |

| PC+ABS Trinseo-CELEX 5200HF | Flame retardant |

| PC+ASA-HRA222F-10000(Cream) | Weather resistance Halogen-free Flame retardant UV resistance |

| PC+ASA-HRA222F-7T2D242 | Weather resistance Halogen-free Flame retardant UV resistance |

| PC-LEXAN 500R-131-NT | Flame retardant High impact resistance |

| PC+GF10-MAKROLON 9415 (Beige) | High viscosity |

| PC+GF20-9425 000000 (Beige) | High rigidity Good dimensional stability Heat resistance Impact resistance Electrical insulation |

| Material Name | Characteristics |

|---|---|

| PA6 (Nylon 6) | Tough, wear-resistant, absorbs moisture, good fatigue strength |

| PA66 (Nylon 66) | Stronger, more heat resistant than PA6, good wear performance |

| PA12 VESTAMID CW1407 black | High flow length-to-thickness ratio Chemical resistance General purpose Good thermal stability Thermally stable |

| PA12 GRILAMID TR90 | Transparent, food safe Biocompatibility |

| PA6 ULTRAMID B3S | Oil resistance Easy to process Crystalline High flowability |

| PA6-N1001-9R033-BK | Good toughness High mechanical strength Wear resistance Good processability |

| PA6-TECHNYL PROTECT C50H1-NT | Aging resistance Halogen-free flame retardant |

| PA6-Novamid 1010C2 | High rigidity |

| PA6 GB30 Latamid 6 S/30 | High dimensional stability |

| PA6-G20 UVNC004 | Dimensional stability Excellent appearance |

| PA6-ULTRAMID B3EG6-NT | FDA food safety compliance Fuel resistant EC 1907/2006 (REACH Compliant) |

| PA6 BKV30 H2.0 901510 | Aging resistance High heat resistance Bio-based |

| PA66-TECHNYL-A-202-NC-J | Anti-ultraviolet Good self-lubricating properties |

| PA66-ZYTEL 101L NC010 (White) | Oil resistance Easy to process Wear resistance Fatigue resistance High fluidity |

| PA66-N3215-Off-WT | High strength High modulus Heat resistance Wear resistance Good chemical resistance |

| PA66-ST801 NC010 (Beige) | High impact resistance |

| PA66-A0520FN-03-NT | High toughness Easy to process Flame retardant High rigidity |

| PA66-Vydyne 22HSP NT | High toughness Oil resistance Heat resistance High strength Wear resistance High rigidity Chemical resistance |

| PA66+PTFE15+GF30 R-FL4036U | UV resistance Wear resistance |

| Grivory GV-2 FWA black 9225 PA | Drinking water germany certification KTW Drinking water UK certification WRAS European food certification FDA food safety standards Drinking water-related NSF ACS unspecified grade Aromatic |

| Material Name | Characteristics |

|---|---|

| PA6+GF15 | Improved rigidity and dimensional stability over unfilled PA6 |

| PA6+GF30 | High stiffness and mechanical strength; reduced ductility |

| PA66+GF30 | Very high strength and stiffness; good chemical resistance |

| PA12+30GF-LV-3H BK9288 | Good Heat Resistance Good Impact Resistance Hydrolysis Resistant UV Resistant |

| PA6+GF15-ULTRAMID B3EG3(Cream) | High toughness High impact resistance Fuel resistant EC 1907/2006 (REACH Compliant) |

| PA6+GF20-NB-60142LU3-U (Black) | UV resistant Good lubricity Good strength |

| PA6+GF30-AKULON K224-G6 (OW) | Low warpage |

| PA66+GF13 ZYTEL 70G13L NC010 | Heat resistance High strength High rigidity |

| PA66+GF15 -N3215 (Off-While) | Good wear resistance Self-lubricating properties Solvent resistance |

| PA66+GF25-FR50 BK505 | Flame retardant |

| PA66+GF25-A3X2G5 BKQ724(Black) | Oil resistance Flame retardant |

| PA66+GF25-ULTRAMID A3X2G5-BK | Oil resistance Flame retardant |

| PA66+GF25-FR50 | Flame retardant |

| PA66+GF30 -VYDYNE R530H NAT | Chemical resistance |

| PA66+GF30 Mapex_A0520FN-03 (Natural) | High toughness Easy to process Flame retardant High rigidity |

| PA66+GF33-70G33L NC010(OW) | High strength |

| PA66+35GF Bangkai N3235 | Good wear resistance Self-lubricating properties Solvent resistance |

| Material Name | Characteristics |

|---|---|

| PEEK | Exceptional thermal, chemical, and mechanical performance |

| PEEK VICTREX 450G903 Black | Food grade Semi-crystalline High strength Ductility High rigidity High flowability Chemical resistance |

| Material Name | Characteristics |

|---|---|

| PEEK+GF30 | High stiffness and heat resistance; reduced ductility |

| PEEK+GF30-KetaSpire KT-880(BK) | Easy to process Wear resistance Acid resistance High purity Fatigue resistance High flowability Chemical resistance |

| Material Name | Characteristics |

|---|---|

| Delrin (Acetal Homopolymer) | High stiffness, low friction, good dimensional stability |

| POM (Acetal Copolymer) | Similar to Delrin but better chemical resistance, lower porosity |

| Material Name | Characteristics |

|---|---|

| PP (Polypropylene) | Excellent chemical resistance, fatigue resistant, soft, low-cost |

| PP-YONGSUX 5090T-TSL | High light transmittance Chemical resistance FDA food safety standards Copolymer Medical biocompatibility |

| PP-YUNGSOX PP 3015-TSL | Low-temperature resistance High impact resistance High rigidity |

| YUNGSOX® PP 3040C NC | High impact resistance |

| Material Name | Characteristics |

|---|---|

| Ultem 1000 (PEI) | High strength and thermal resistance, inherently flame retardant |

| PEI-ULTEM 1000 | Heat resistance Aging resistance Wear resistance High rigidity Transparent |

| Material Name | Characteristics |

|---|---|

| PEI+GF30-ULTEM 2300 (Black) | High Heat and Chemical Resistance Excellent mechanical stability Amorphous |

| PET+GF30- FR530 NC010 (Beige) | Heat resistance Wear resistance Flame retardant High rigidity |

| Material Name | Characteristics |

|---|---|

| UHMWPE | Very low friction, abrasion-resistant, self-lubricating |

| HDPE | Chemically resistant, lightweight, tough, low moisture absorption |

| HDPE-PURELL GC 7260-TSL | Low warpage High impact resistance Stress crack resistance High density High toughness High rigidity Excellent processability Good flowability |

| LDPE PURELL 2410T | Excellent processability Compatible with ethylene oxide sterilization Low density |

| Material Name | Characteristics |

|---|---|

| PS (Polystyrene) | Rigid, brittle, low-cost, easy to machine, poor chemical resistance |

| Material Name | Characteristics |

|---|---|

| PBT | Tough, wear- and chemical-resistant, good dimensional stability |

| PBT-Valox 325-7001-BK | Improved flowability |

| PBT-FA115Z TDS | Low warpage Good dimensional stability Good electrical properties High flowability |

| PBT-Valox 420 SE0 1001 | Heat resistance High strength Dimensional stability High rigidity |

| Material Name | Characteristics |

|---|---|

| Teflon (PTFE) | Extreme chemical resistance, non-stick, low friction, soft |

| Material Name | Characteristics |

|---|---|

| PET | Hard, low wear, excellent dimensional stability and creep resistance |

| Material Name | Characteristics |

|---|---|

| PVC | Rigid, flame-retardant, chemical-resistant, economical |

| Material Name | Characteristics |

|---|---|

| PPSU | Extremely tough, hydrolysis- and impact-resistant, sterilizable |

| PPSU Radel R-5100 BK937 | Heat resistant, stable, flame retardant |

| Material Name | Characteristics |

|---|---|

| Fiberglass (G10/FR4) | High strength, excellent electrical insulation, flame retardant |

| Material Name | Characteristics |

|---|---|

| Bakelite (Phenolic Resin) | Thermoset; hard, brittle, good electrical and heat resistance |

| Material Name | Characteristics |

|---|---|

| ASA LURAN S 778T | UV resistant Heat resistant Weather resistant General purpose |

| Material Name | Characteristics |

|---|---|

| GPPS Polyrex PG-383M | High strength Transparent High light transmittance |

| Material Name | Characteristics |

|---|---|

| PCTG-TRITAN TX1001-CR | Food safe High purity Chemical and heat stable Good stiffness |

| PCTG-TRITAN TX2001 (Transparent) | Hydrolysis resistance Easy to process High impact resistance Heat resistance Chemical resistance Transparent |

| PCTG TRITAN MX711 | Medical sterilization X-ray and radiation stable High toughness and heat resistance Biocompatible |

| Material Name | Characteristics |

|---|---|

| PETG-EASTAR GN071-CR | Food safe, clear, excellent appearance |

| Material Name | Characteristics |

|---|---|

| POM-DELRIN 500P NC010 (White) | Weather resistance Aging resistance High rigidity General purpose Self-lubricating |

| POM-KEPITAL F10-03H-WT | High resistance to heat, wear, creep, fatigue, and chemicals |

| POM-HOSTAFORM C9021 (White) | Wear resistance General purpose |

| POM Delrin 527UV NC010 | UV resistance |

| POM-TEPCON® M90-CF2001(PL) | Chemically resistant, Excellent wear |

| POM-DURACON M270-57 | Wear resistance High flowability Chemical resistance |

| Material Name | Characteristics |

|---|---|

| PPO-NORYL SE1GFN3-701-BK | Low warpage, shrinkage, water absorption, density, creep sensitivity |

| PPE/PPO NORYL Resin GFN1 | Heat resistance High strength Dimensional stability |

| Material Name | Characteristics |

|---|---|

| PPS-Fortron 1140L4 SD3002 BK | Heat resistance Reinforced Flame retardant |

| PPS-A660HVB(T043545) | Chemical resistance Flame retardant High heat resistance Tracking resistance |

| Material Name | Characteristics |

|---|---|

| PPS+GF40-RYTON R-4-200BL (BK) | High strength |

| Material Name | Characteristics |

|---|---|

| TPE S EH 80A-3S7005 | UV resistance General-purpose |

| Material Name | Characteristics |

|---|---|

| TPU-ELASTOLLAN 1185A (TL) | Hydrolysis resistance Low-temperature impact resistance Mold and antibacterial resistance |

| TPU-BASF Elastollan S85A | Weather resistance Flame retardant UV resistance |

| TPU-Elastollan B 64DCF | Wear resistance High elasticity Low-temperature flexibility |

| Material Name | Characteristics |

|---|---|

| TPV-SANTOPRENE 291-75B150 (BG) | Adhesive (Bondable) |

| TPV-Santoprene_201-55 | Low-temperature resistance Heat resistance Aging resistance Chemical resistance |

| TPV SANTOPRENE 8211-65 | Flexibility Heat resistance Weather resistance Good sealing properties Easy processing |

"I was absolutely thrilled to receive my parcel today. The craftsmanship is exceptional — the visual clarity is even greater than I imagined, and the precision of the machining is evident in how perfectly everything aligns during my initial test fitting. I also want to express my appreciation for your excellent communication throughout this process and your commitment to working closely with me as an individual on such a custom project. It really made the experience smooth and enjoyable."

Christopher

Founder

What Our Customers Say

- Christopher

Procision’s manufacturing environment is purpose-built to deliver to the most exacting standards — ensuring every material, tolerance, and process meets or exceeds your specifications. Whether through rapid prototyping services or rapid manufacturing, our commitment to precision, consistency, and continuous refinement goes beyond results. We deliver the confidence you need, knowing that every part is crafted to your exact specifications and backed by our unwavering dedication to excellence.

Our commitment to operational efficiency and to a strong focus on customer satisfaction.

Our commitment to quality, consistency, and safety in the custom manufacturing of medical components.

Common Questions

Our manufacturing services include multi-axis CNC milling and turning, toolmaking, plastic injection molding, micro molding, polyurethane vacuum casting, sheet metal fabrication and painting. Our partners also provide anodizing, metal plating, laser etching, waterjet cutting and more.

For CNC milling and turning, we comply with DIN / ISO 2768-medium and fine for most jobs, but we can achieve higher tolerances upon request. We also follow the standard guidelines of the Plastics Industry Association for toolmaking and injection molding. More detailed tolerance information can be found here.

Prototypes prioritize speed and economy. To achieve this, they may feature looser tolerances and employ less robust material that’s easier to fabricate. Production parts must achieve higher tolerances consistently, with better fit and finish. This requires longer development lead times with more careful design and engineering input

All incoming raw materials are carefully tested and verified before going into production. We also perform in-process inspection at every step, as well as a thorough final inspection backed up with complete test reports and certificates of compliance. We are proud to be compliant with ISO 13485 and 9001 standards and we also have prefered AEO customs clearance certification.