From Prototyping To Mass Production

On-demand Plastic Injection Molding Services

Get custom plastic parts, manufactured fast and reliably.

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

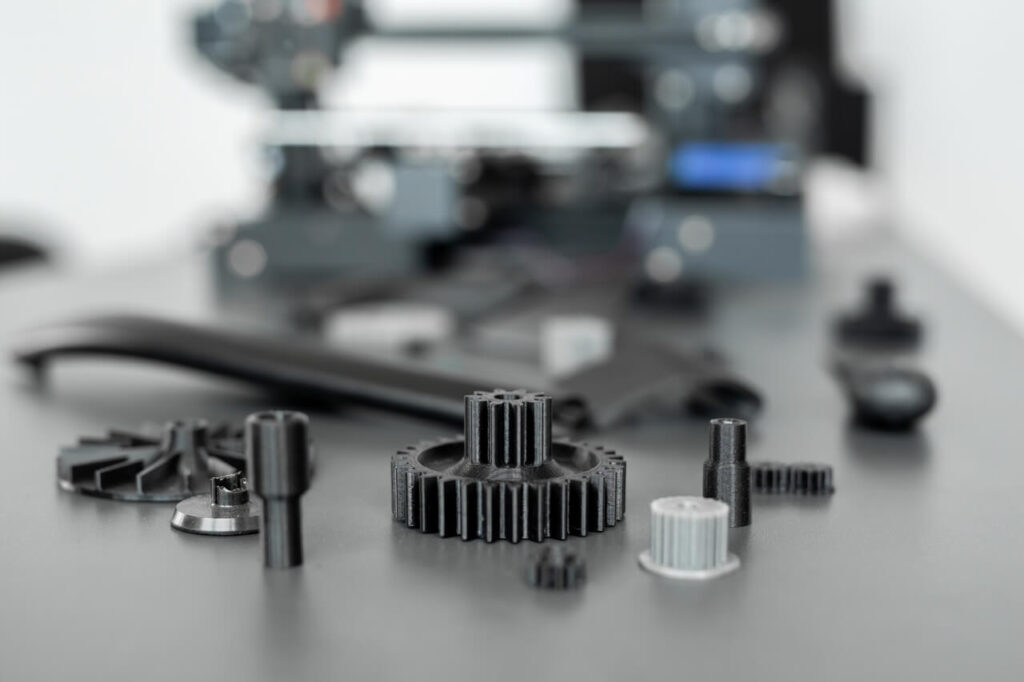

Plastic Injection Molding

High-Quality Custom Plastic Injection Molding Service

Your projects deserve reliable manufacturing solutions that deliver accuracy, consistency, and speed. If you’ve been let down by poor quality, missed deadlines, or unreliable suppliers, we’re here to change the narrative. Our plastic injection molding service offers an experienced international team of manufacturing specialists, so you can trust that your parts will meet the highest standards and be delivered on time, every time.

Procision Manufacturing

The Plastic Injection Molding

Plastic injection molding is a process where liquid plastic resin is injected into a mold under high pressure where it cools and solidifies to form a finished part. Depending on the tool design, molds can produce single or multiple parts in each cycle, enabling efficient large-scale production.

Here’s how the injection molding process is streamlined to minimize waste and maximize consistency:

- Preparation: Raw plastic pellets are dried and, if needed, mixed with pigments or colorants for precise color matching.

- Feeding and melting: Dried pellets are loaded into the machine’s hopper where they’re heated and mixed with a reciprocating screw until molten.

- Injection and cooling: Molten resin is injected into a custom mold under high pressure, then rapidly cooled to retain its shape.

- Ejection and inspection: Finished parts are ejected, inspected, and prepared for your use.

This process ensures reliable results, batch after batch

Procision Manufacturing

Expertise Tailored to Your Needs

Receive custom parts that meet your unique requirements:

- Versatile material options: Work with thousands of resins, including nylon, ABS, HDPE, polypropylene, acrylic, PTFE, and more. Whether you need durability, flexibility, or a specific finish, we’ve got you covered.

- Precision and quality: Skilled technicians ensure accuracy, precision, tight tolerances, and exceptional surface finishes, reducing costly errors and rework.

- Flexible production volumes: From low-volume prototyping to high-volume manufacturing (50 to 100,000+ parts), adapted to your needs without compromising quality.

Custom tooling: Production mold tools crafted using premium materials like S136H, H13 hardened steel, NAK80, and P20, ensuring durability and accuracy.

Procision Manufacturing

Benefits of Plastic Injection Molding

Plastic injection molding is the ideal manufacturing solution for making high volumes of identical plastic parts. The process offers accuracy and excellent surface quality, extensive material options for varied applications, flexible color customization, and durable tooling for repeated use.

Whether you’re scaling production or creating intricate designs, injection molding provides a reliable and cost-effective pathway to success.

Thousands of resins

Economies of scale

Stable and repeatable

Surface quality

Design Flexibility

Common Questions

Frequently Asked Questions About Plastic Injection Molding

Find answers to common questions about injection molding manufacturing, mold design, and how industries like medical, electronic, agriculture, and consumer products can achieve their goals.

What are injection molding services?

Plastic injection molding services produce high-quality parts quickly and efficiently from a wide selection of resins, including high-density polyethylene (HDPE), acrylic, polypropylene, polycarbonate, and acetal or polyoxymethylene (POM). Procision Manufacturing specializes in injection molding projects of all sizes, from on-demand prototyping to high-volume production, ensuring low-cost solutions with no minimum order requirements.

What is the injection molding process?

Injection molding begins with drying raw plastic pellets, which may be blended with colorants. These pellets are melted and mixed inside the injection molding machine, forming a semi-liquid resin. The resin is injected under high pressure into a custom mold, filling the cavity to create the part. Once cooled, the part is ejected and the cycle repeats. Insert molding can also be integrated to enhance the final product’s functionality.

What are the advantages of injection molding?

Your precision parts will benefit from careful mold design and manufacturing which yields excellent surface finishes, tight tolerances, and material versatility to suit your needs.

What are the main cost drivers for plastic injection molding?

Costs vary based on a number of factors, such as mold complexity, material, and production volume. While higher volumes reduce per-unit costs, Procision’s low-cost solutions also ensure affordability for low-volume productions and prototyping.

What should you expect from a plastic mold manufacturer?

A reputable plastic mold manufacturer ensures every step of the process is meticulously controlled for consistent, high-quality results. This starts with the accurate identification of raw materials and continues through each phase of production to guarantee process repeatability. Full ISO certification is a testament to their dedication to quality and operational excellence.

How long does it take to make an injection mold tool?

The cost of a plastic injection mold tool can be a significant percentage of the total order for small volumes. However, this cost can be amortized over larger volumes so that it doesn’t become an issue. Rather, plastic resin and cycle times become the main cost drivers for larger volumes.

How can I reduce mold costs?

While it’s tempting for a project developer to prioritize upfront savings, opting for a low-cost mold tool often leads to poor quality, reduced durability, loose tolerances, and subpar surface finishes. These are not cost savings — they’re expensive mistakes. Instead, focus on long-term savings through production efficiency, faster cycle times, and stable processes. Over time, as production increases, the relative cost of a high-quality tool becomes negligible.

What makes Procision’s injection molding service special?

Procision Manufacturing combines extensive expertise with industry-leading facilities to deliver unmatched injection molding services. We handle projects of all sizes, from micromolding (10 tons) to large-scale parts exceeding 500 tons, covering dimensions from millimeters to cubic meters. OurThe team includes seasoned tooling experts who provide personalized support, including video consultations, ensuring a seamless and efficient experience tailored to your unique needs.

What types of tools and resins do you offer?

Tools and dies are manufactured using high-grade materials like S136H, 2316H, H13 hardened, P20, 8407, and NAK80 semi-hardened steels. Finishing options include SPI standard finishes, EDM texturing, and various etched textures. Additionally, choose from thousands of thermoforming plastics to meet diverse application requirements. Contact us for detailed information on available plastic materials.

Does Procision offer design services or custom parts manufacturing support alongside molding?

Absolutely. Every order undergoes a comprehensive review by our tooling engineers to ensure design for manufacturing (DFM) optimization.

What are Procision's quality standards for plastic injection molding services?

Rigorous quality control ensures safe and high-performing products for our clients. As with all our services, we perform detailed material verification and testing before production, covering both mold metals and plastics.

Throughout the production process, we maintain strict control over environmental factors like temperature and humidity to guarantee repeatable results, setting us apart from competitors who often overlook these critical steps. We also 3D scan complex shapes to ensure dimensional accuracy.

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

Why Choose Us

Why Choose Procision for Plastic Injection Molding?

Comprehensive Services

Your parts deserve more than just molding but a complete, custom manufacturing solution. With a seamless process that handles everything from mold design to final inspection, you can trust every step will be completed efficiently and on time, even under tight deadlines.

Material Compliance

Positive Material Identification (PMI) helps you meet regulatory requirements with transparency, compliance certifications, and traceability, offering peace of mind for critical projects. People trust Procision when the job must be exactly right.

Design Optimization

Need parts quickly? Efficient processes and rapid smart quoting system — always vetted by a human professional — ensure delivery that meets even the tightest deadlines without compromising quality. You’ll be informed every step of the way, with transparent pricing and proactive updates.

Fast Turnarounds and Clear Communication

The comprehensive design-for-manufacturing process enhances functionality and reduces lead times, ensuring a seamless injection molding project every time. You’ll save time and money while receiving superior results.

Common Questions

Procision Plastic Injection Molding Service FAQ

How long does it take to make an injection mold tool?

This depends on the complexity of the tool design and the type of material the tool is made from. Generally speaking, a very basic square shape made from relatively soft steel such as P20 can be made in less than one week. Very hard steels take longer to cut and to heat treat, while complex shapes or advanced surface textures can require three or more weeks to prepare.

What should you expect from a plastic mold manufacturer?

A reputable manufacturer will positively identify all incoming raw materials, and will carefully control every stage of production to ensure process repeatability. Full ISO certification is a good demonstration of their commitment to excellence.

How can I reduce mold costs?

A product developer should be looking to save money on the cost of a mold tool. In most cases, a less expensive tool is going to be of poorer quality, less durable, with looser tolerances and a bad surface finish. These are not cost-savings. Instead, they’re expensive mistakes. Rather, savings can be made long-term through production efficiency, fast cycle times, and process stability. As volumes increase, the relative cost of the tool goes down until it’s almost free.

What makes Procision’s injection molding service special?

Our molding service is strengthened by our extensive expertise and a wide range of production capabilities. Our industry-leading facilities allow us to handle projects ranging from micromolding (10 tons) to large projects over 500 tons. This means we’re capable of producing parts ranging from millimeters to cubic meters in size. Our production of such a wide variety of parts enables us to best meet your needs. Further, we have unique access to tooling experts with decades of experience. They are available for video conferencing and customer support. We’re united in our efforts to help you have a satisfactory injection molding experience!

What types of tools and resins do you offer?

We make tools and dies from S136H, 2316H, H13 hardened, 2316H, P20, 8407, and NAK80 semi-hardened steels. We offer standard SPI finishes, EDM texturing, and several different types of etched textures. We also have thousands of thermoforming plastics available – contact us for details.

What are Procision’s quality standards for plastic injection molding services?

Our quality-control system includes several steps to ensure safe, high-performing products for our clients. As with all of our services, we conduct comprehensive material verification and testing before molding begins. This includes the metal used in our molds and the plastics used in production. During production, we carefully control all processing conditions – including temperature and humidity – to maintain repeatable results. Many molding companies neglect to do this, which can lead to flaws in the finished parts. We also 3D scan complex shapes to ensure accuracy.

Applications Tailored to Your Industry

Our high-quality custom injection molding services support a wide range of prototyping and manufacturing applications:

Plastic Injection in the Medical Industry

Lightweight, non-toxic, and precisely molded parts for syringes, tubing, dispensers, catheters, and other essential medical devices.

Plastic Injection in Consumer Products

Durable and stylish components for home appliances, toys, and other products. From computer keyboards and mice to headphones, game controllers, and kitchen gadgets, plastic compounds with diverse chemical properties make it all possible.

Plastic Injection in the Agriculture Industry

Robust, lightweight, non-conductive housings for circuit boards, switches, wires, batteries, and sensors. These safeguard both the component and the user.

Plastic Injection in the Electronics Industry

UV-resistant and chemically durable parts for tools, sprinklers, conveyor belts, drive trains, feeders, fencing, and much more.

Procision Manufacturing

Controlling Plastic Molding Tolerances to Solve Your Challenges

Plastic resins can be unpredictable, reacting to temperature, moisture, and mechanical stress in ways that might cause expansion or contraction. These challenges can impact the integrity and functionality of your parts, but they don’t have to. Our commitment to accuracy and reliability helps you avoid these pitfalls and provides exceptional results.

The comprehensive product design analysis will, identify potential trouble spots in your design — whether it’s thermal stress, warping, or shrinkage. These proactive measures ensure that your injection-molded parts maintain their intended shape, strength, and performance. If you’re looking for actionable guidance, our manufacturing design guide highlights common defects and proven strategies to avoid them.

Request Your Free Injection Molding Quote Today

Ready to start your next project? You deserve a partner who values your success. Submit your project details and optional 3D files, and our skilled engineers will promptly analyze your custom plastic injection molding requirements.