From Prototyping To Mass Production

Micro Injection Molding Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Procision Micro Molding

Micro Molding Services: Precision Parts You Can Rely On

Need fast, accurate parts with reliable quality? Procision’s micro injection molding service provides the perfect solution for your small, intricate plastic components. Whether you’re facing quality issues with previous suppliers, dealing with long lead times, or struggling with inconsistent results, we’re here to offer the accuracy and reliability you need.

Procision Micro Molding

Why Micro Injection Molding?

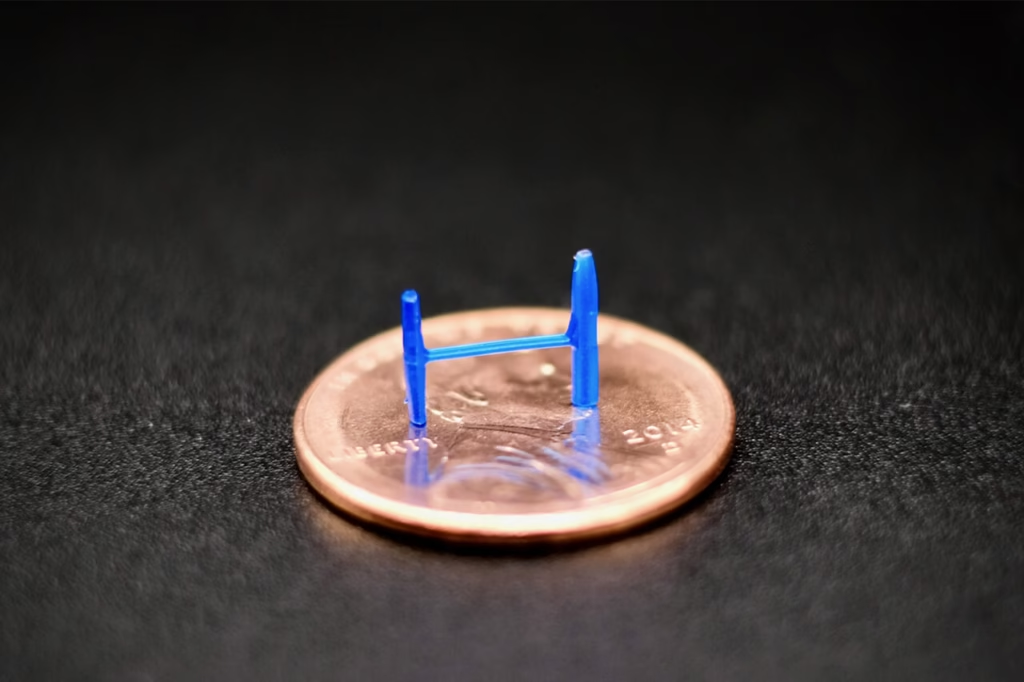

Micro injection molding is the most advanced way to produce ultra-small plastic parts with tight tolerances. It’s not just about using smaller machines; it’s about mastering the technology and understanding the complexities involved in manufacturing small parts, sometimes with intricate geometries.

The secret is the control and distribution of heat within multiple small, close-proximity cavities, a task handled by advanced temperature sensors and digital microcontrollers that surpass the accuracy of larger systems.

Benefits of Micro Injection Molding

Here’s how micro-injection molding addresses your most pressing challenges:

- Compact barrel design: Shorter barrels reduce cleaning times during material changes, such as switching between polycarbonate and polystyrene.

- Faster cycle times: The reduced barrel length minimizes travel distance, leading to quicker injection cycles and significantly decreasing overall production time.

- Material efficiency: Micro molding uses far less resin, which not only lowers material consumption but also contributes to cost savings.

- Cost-effective tooling: The smaller scale of micro molds reduces the cost of hard tools, enabling these savings to be passed directly to the customer.

- Accelerated tool production: Creating tools for micro molding requires less machining time, which shortens lead times and speeds up the manufacturing process.

- Enhanced accuracy: Micro injection molding delivers exceptional accuracy and precision, making it ideal for manufacturing intricate components with tight tolerances.

- Reduced waste: The micro injection molding process minimizes waste generation, aligning with sustainability goals and reducing disposal costs.

- Uncompromising quality assurance: Close monitoring and inspection help ensure that even the smallest components meet quality standards, enhancing reliability and performance.

- Scalability for diverse production needs: Micro injection molding is suitable for both small production runs and large-scale manufacturing, providing flexibility for various project demands.

- Compatibility with advanced materials: The process accommodates a wide range of innovative materials, including high-performance polymers and biocompatible resins, expanding its applications across industries such as medical, electronics, aerospace, and automotive.

Procision Manufacturing

Applications For Micro Molding Injection

Micro injection molding is perfect for industries that require small, high-precision parts. From medical devices to cutting-edge electronics and other applications where accuracy and tight tolerances are paramount, micro injection molding solutions are ideal for example:

- Medical devices: Implants, wearables

- Electronics: Smartphones, sensors

- Robotics: Lightweight, durable components

- Consumer Products: Accurate components for everyday devices

Micro injection molding is the ideal choice when you need consistent, reliable precision and accuracy you can trust.

Medical Wearables

Surveillance Equipment

Fitness Trackers

Robotics

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

Common Questions

Procision Micro Injection Molding Service FAQ

Find answers to common questions about micro plastic injection molding services, mold design, and how these services help industries like medical, electronic, agriculture, and consumer products achieve their goals.

What is micro injection molding?

Micro injection molding is a highly specialized manufacturing process designed for producing micro parts with intricate geometries and micro-featured details. Like traditional injection molding, high-pressure resin is injected into a mold cavity and cooled to create a plastic part or component. However, this technique leverages precision tool design and advanced injection units to create components with exceptional detail fidelity, such as thin walls and high-resolution features.

What is the process of micro molding?

Micro molding creates extremely small thermoplastic parts with micron tolerances, starting with a precisely engineered mold.

What are the advantages of micro injection molding?

Benefits include exceptional precision, cost savings, faster production times, and reduced material waste.

What is the smallest part micro molding can produce?

Part size depends on gate dimensions. Shot weight is limited to a few grams, and typical part size is around 3mm². If you need part sizes smaller than this, request a quote to discuss your project with experienced engineers.

Can any type of plastic resin be used for micro injection?

Most resins are supported, though additives like glass fibers may affect flow through small gates.

How much does micro injection molding cost per hour?

Machine rates for injection molders can vary significantly based on numerous factors such as machine tonnage, material type, and project complexity. For a detailed and accurate estimate tailored to your project, request a quote today.

How do you calculate molding cost?

Molding costs are calculated as the sum of three primary components:

- Material cost – The cost of raw materials used in the mold.

- Manufacturing cost – Expenses incurred from mechanical work during the molding process.

Overhead cost – Indirect costs such as utilities, administrative expenses, and other costs associated with mold production that aren’t directly machine-related.

What are the techniques of micromolding?

Micromolding involves specialized techniques for creating precise microstructures in polymers using molds (also referred to as masters or tools). Three most common techniques are:

- Injection molding – Ideal for high-precision and high-volume production.

- Hot embossing – A process that uses heat and pressure to imprint microstructures.

- Casting – A technique that involves pouring material into a mold to form intricate features.

Each technique offers unique advantages depending on your project’s requirements.

How durable are micro molding tools?

Tools are equally durable as their full-sized counterparts, often lasting over 100K cycles depending on the resin used.

How do I get micro injection molding services?

Getting started with micro injection molding is easy. Simply request a personalized quote, and our team of experienced specialists will guide you through every step of the manufacturing process – from initial design and material selection to final production and delivery. Let us ensure your project’s success with expert support at every stage.

Why Choose Us

Why Choose Procision for Micro Molding

When accuracy, quality, and reliability are non-negotiable, Procision Manufacturing delivers micro molding solutions you can trust. If you’ve been burned by unreliable suppliers, struggled with inconsistent quality, or faced delays, our team is here to ensure your micro molding project is a success.

Here’s what makes us the preferred partner for small-scale plastic part manufacturing and how we will meet your mico molding needs:

Proven Track Record of Success

With years of experience and a strong reputation for quality, our clients trust us to solve their most complex molding challenges. From rapid prototyping to full-scale production, you can count on us to deliver on-time, on-budget results every time.

Seamless Communication for a Smooth Experience

Transparent communication is critical to your project’s success. Our team works with you every step of the way, providing clear updates, real-time responses, and full support throughout the manufacturing process.

Certified Quality Assurance

Certifications like ISO 9001, 14001, and 13485 ensure the highest international standards for quality, environmental responsibility, and regulatory compliance. You can trust us with your most critical micro molding projects.

Flexible, Scalable Solutions

Whether you need a small batch or a large production run, micro injection molding offers flexibility. With services scaled to fit your needs, you get the right amount of parts when you need them.

Procision Manufacturing

Micro Molding

Micro molding service feature:

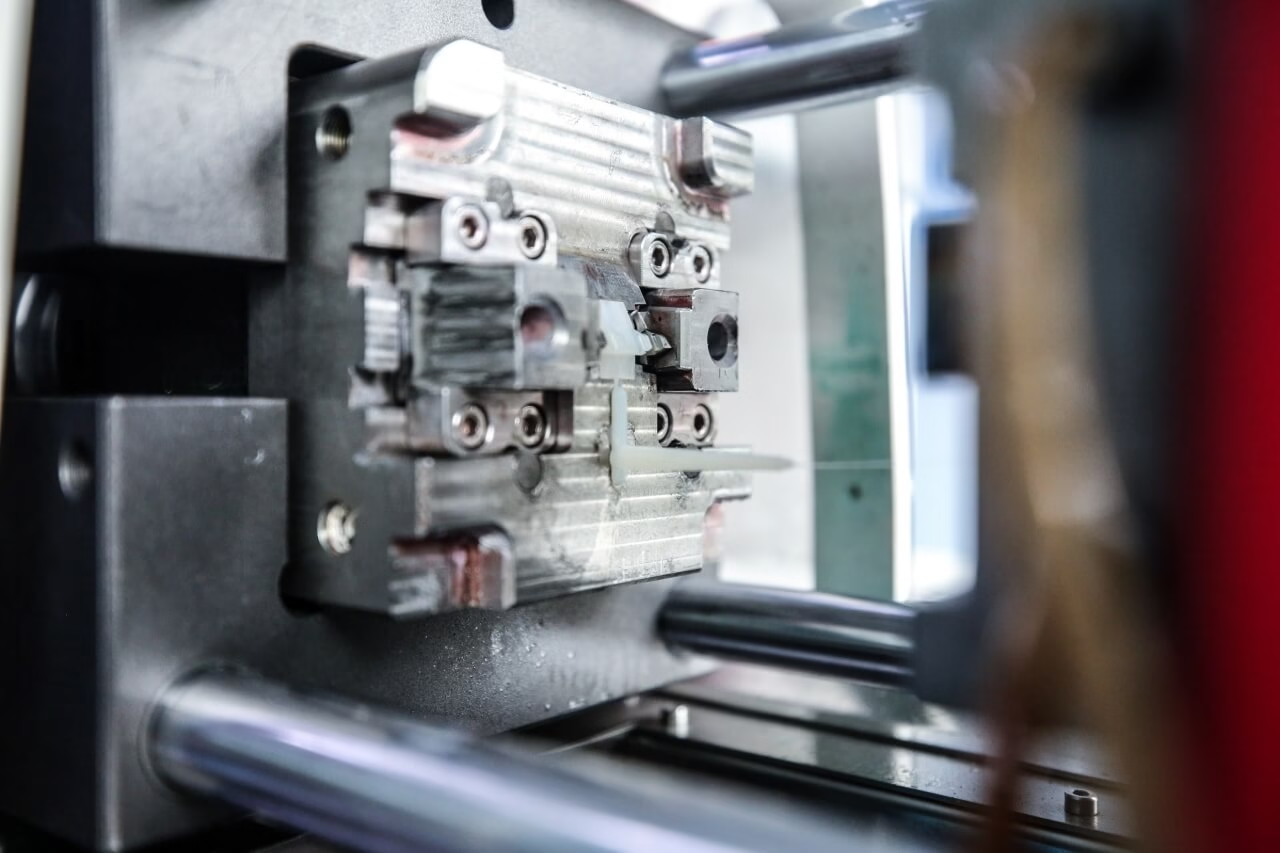

- Precise temperature and pressure control: Ensuring consistent results and maximum efficiency.

- Cost-effective steel tools: Up to 40% less expensive than full-sized alternatives.

- Digital process parameters: For consistency and fast set-ups.

- Fully electrical drive: This makes Babyplast machines fast and clean, so they are suitable for use in cleanroom environments such as the one at Procision Manufacturing.

These injection molding machines exemplify the quality and efficiency your project requires.

Considering Micro Molding for Your Next Project?

Ready to get your project off the ground? Request a free quote and let’s discuss your micro molding needs today! We’re here to help you with fast, reliable, and accurate manufacturing for your next part or project.