From Prototyping To Mass Production

On-Demand Low-Volume Manufacturing Services

Fast and Reliable Custom Manufacturing Solutions When You Need Them

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Step 1

Upload Design

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Quote & DFM

Step 3

Manufacturing

Step 4

Shipping

Procision Low-Volume Manufacturing

Tailored and Versatile Low-Volume Manufacturing Services

No MOQ (Minimum Order Quantity)

There’s no minimum order quantity at Procision. Whether you need low-volume CNC machining for a single prototype or low-volume plastic manufacturing for a short production run, your parts receive the same rigor, traceability, and technical care—every time.

Seamless Scaling Up

Start small and scale with confidence. Our flexible manufacturing system supports your path from prototype to full-volume production, reducing upfront risk while protecting your long-term strategy.

Procision Low-Volume Manufacturing

Your Vision, Our Expertise: A Superlative Combination

Clear Communication from Day One

Dedicated engineering project managers keep your team informed at every stage with timely updates, transparent timelines, and direct answers—so you’re never left guessing.

Support at Every Stage of Development

From early-stage concepts to pilot runs and full production hand-off, our engineers help you overcome technical barriers to deliver low-volume custom parts that meet your spec, schedule, and budget.

Low-Volume Manufacturing Services

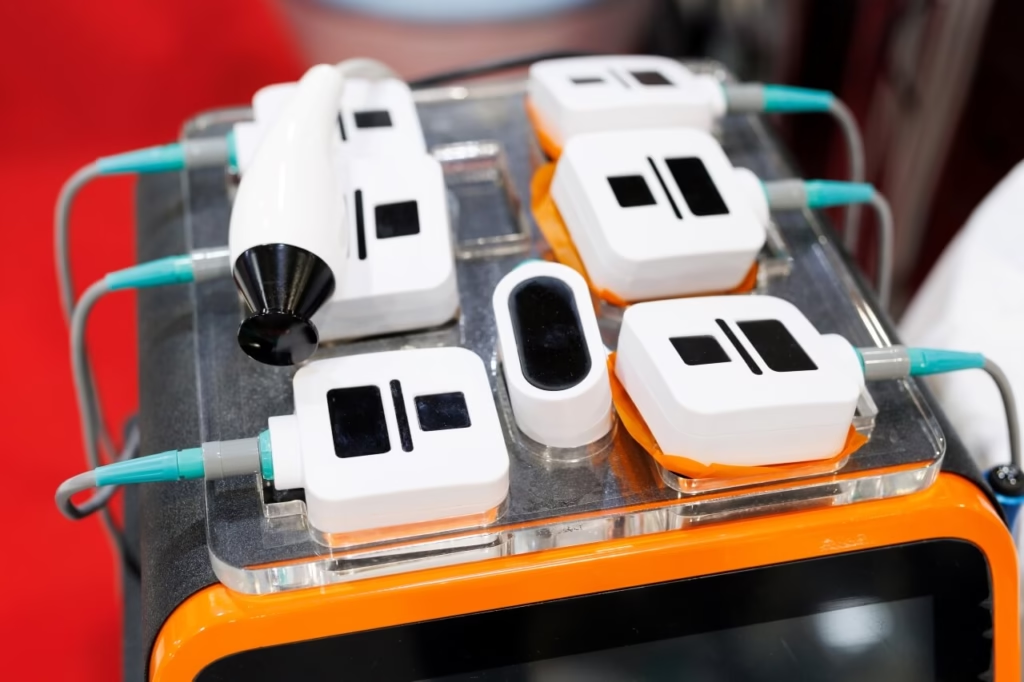

Plastic Injection Molding

Accelerated tooling and low volume production for high-quality, cost-efficient plastic parts—ideal for low-volume validation builds, short runs, or market-ready product batches.

Polyurethane Vacuum Casting

Fast, flexible, and affordable casting for prototype and short-run plastic components using reusable silicone molds.

CNC Machining

Precision-machined parts, delivered fast—without fixed tooling or long lead times. Machined in-house to your exact specs by experienced professionals.

Why Partner with Procision Manufacturing?

Procision helps product developers produce critical parts in low volumes—without compromising on quality, compliance, or cost. Here’s how we help you succeed:

DFM on Every Project

Every job includes early-stage Design For Manufacturability guidance. Our engineers work with you to optimize part designs for cost, tolerances, materials, and production timelines.

Raw Material Verification

All incoming materials are inspected and validated using precise analytical tools. You’ll receive full traceability, test data, and certificates of compliance to support your QA goals.

Rigorous Quality Control

Critical-to-function features are inspected at every stage—dimensionally and visually—to ensure you get exactly what you need: consistent tolerances, textures, and finishes.

Intelligent Quotations

You won’t get a generic price from an AI form. An experienced engineer evaluates your custom parts for cost-saving insights and realistic lead times—so there are no surprises later.

Global Delivery, Simplified

We ship worldwide with trusted logistics partners and preferred customs clearance. No bottlenecks—just fast, traceable delivery of compliant parts, anywhere you do business.

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

Common Questions

Procision Low-Volume Services FAQ

Is all production done in-house?

Most parts are manufactured directly by us in our own facilities, but sometimes we outsource production to one of our partner factories. They work as an extension of Procision, under our strict quality assurance and traceability guidelines. You’ll get the same quality, reliability, and performance as with every part we make.

What are the minimum and maximum order quantities?

There are none. Procision has a flexible manufacturing system to produce quantities from a single prototype to scaled production volumes with no cap.

What are the benefits of low-volume CNC machining?

Custom product developers turn to low-volume CNC machining because it’s fast, versatile, easily scalable, requires no fixed tooling, and finished parts feature precise engineering tolerances.

What are the benefits of low-volume plastic manufacturing?

When market conditions demand repeated small batch production runs over a longer period of time, low-volume plastic manufacturing is the ideal way to keep costs down while maintaining consistency lot-to-lot.

What types of parts can be made in low volumes?

We specialize in metal and plastic components for gear systems, housings, enclosures, mechanical linkages, actuators, connectors, and complete assemblies.

What materials do you support?

Hundreds of metals including aluminum, stainless steel, titanium, Inconel, and brass. Thousands of plastic resins and composites—including high-performance and engineering-grade options.

Why Partner with Procision Manufacturing?

Custom parts developers rely on Procision Manufacturing to provide cost-effective, defect-free and compliant low volume manufacturing services. Here’s how we can help you to meet your strategic goals.

Free DFM for Every Project

We help you cut out the delays and financial losses caused by design inefficiencies by optimising your product designs to reduce production delays, lower costs, and enable smooth transition to mass production.

Raw Material Inspections

Rigorous Quality Control

Every part is meticulously inspected and qualified both for dimensional precision and appearance, so you can rest assured you’ll only receive parts that are defect-free and exceed your expectations.

Intelligent Quotations

Our tailored quotations provide itemized costs that are easy to understand and enable you to budget accurately while avoiding hidden fees.

World-wide Delivery

We have preferred customs clearance to help streamline the logistics and shipping process, allowing you to receive your finished parts anywhere in the world quickly and safely.