Built To Perform

Quality Inspection Services

Ensuring conformance to your exacting specifications, from a single part to unlimited volumes. Contact us to see how we do it.

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

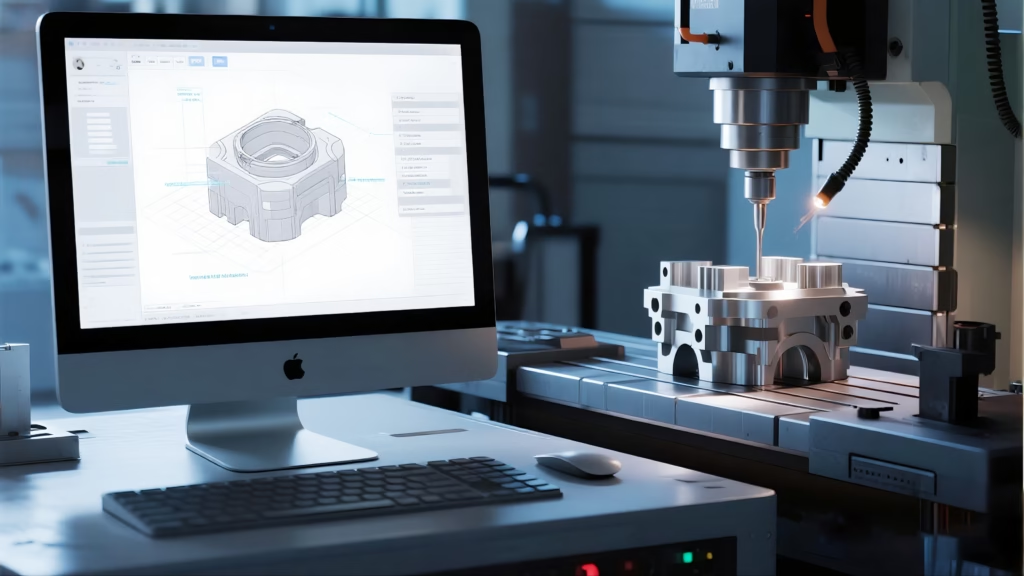

Procision Quality Inspection

Get Flawless Parts Every Time

Defective parts and inconsistent quality are a product designers worst nightmare, especially when working with multiple contract manufacturers and complex supply chains. While others cut corners to get parts out the door, Procision Manufacturing takes pride in uncompromising quality assurance on every order.

Procision Quality Inspection

A Professional Team of Specialists

Our in-house team of 20+ inspectors conduct testing on all incoming materials, as well as first article, in-process, and final inspections. Working in temperature-controlled facilities with advanced digital instruments, we offer accuracy and repeatbility for even the most demanding industries like medical and aerospace.

Quality Inspection Services At Every Production Stage

At Procision, quality is built into everything we do. From material analysis to final certification, all steps are carefully controlled and all quality data are available at your request.

Procision Manufacturing

Pre-Production Quality Inspections

Design for Manufacturing (DFM) Review

After your order is accepted, you will receive recommendations that reduce waste, save money, prevent production delays, and make your parts more manufacturable.

Incoming Material Inspection

We identify, and remove, any potential fraudulent or substandard materials that could impact your regulatory compliance and performance goals.

Contract Reviews

Before production, our team will contact you to clarify any final questions about your project. We’ll ensure all your requirements are understood.

Procison Manufacturing

Material Testing

Our material testing and identification procedures aren’t extra services. We consider them an essential part of every project. Key aspects we analyze include:

- Chemical composition to correctly identify plastic resins and metal alloys.

- Hardness and mechanical resistance to test strength, impact resistance, and the wear properties of raw stock.

- Plastic flow and viscosity to assess how thermoplastics behave during molding to ensure we have the right process parameters.

Procision Manufacturing

Quality Certifications Issued

Get peace of mind with complete documentation that helps you to meet your product certification targets.

- CMM inspection report

- Material certification

- Standard measurement protocol

- First Article Inspection (FAI) report

- Certificate of Conformance (CoC)

- Chain of custody

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

Common Questions

Frequently Asked Questions

What is the difference between quality assurance and quality control?

Quality assurance refers to the standards and procedures used to minimize errors during production. It refers to systemic practices that apply to all production.

Quality control is a corrective approach to identify and correct specific defects found during production on a given part. It is essentially reactive rather than proactive.

Can I see the quality inspections performed on my parts?

Yes, detailed inspection reports are available upon request.

What makes Procision's quality inspection stand out?

We’ve invested in cutting-edge inspection instruments, assembled a team of trained professionals, and defined and followed strict quality protocols. Few others in our field take this same degree of care and attention to detail.