Procision Manufacturing

Metal & Plastic Parts For Medical Device Manufacturing

The medical industry demands precision, quality, and reliability in every component. Achieving this when launching a new device requires navigating complex and rigorous quality, safety, performance, and traceability standards.

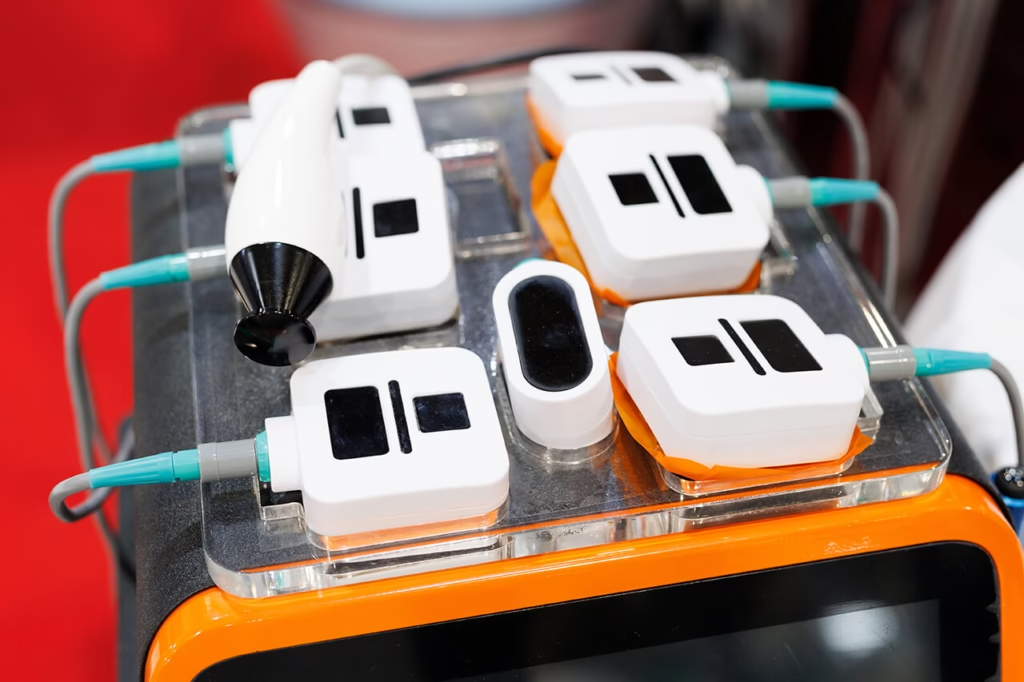

Some examples of medical devices include fitness trackers, health monitors, drug delivery devices, enclosures for medical equipment, prosthetics, and many other medical products.

Procision Manufacturing provides everything you need to overcome these challenges with speed and confidence. We offer custom and tailor-made rapid prototyping, low-volume manufacturing, and tooling services to empower you to quickly iterate, validate designs, test the market, and scale production.

Our medical device manufacturing capabilities include vacuum casting, CNC machining, plastic injection molding and micro molding.

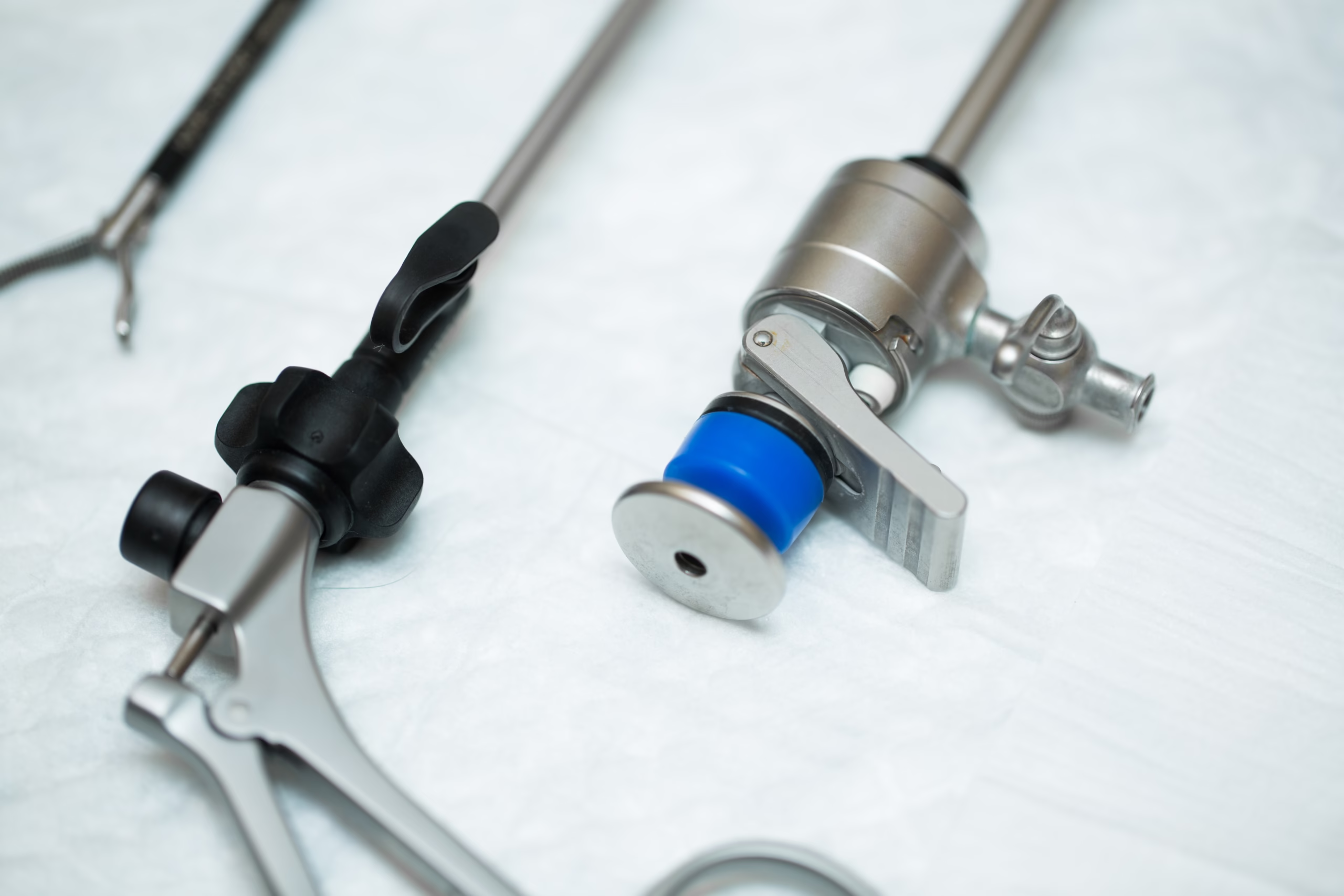

Medical equipment manufacturing relies on a variety of integrated, high-precision methods. Which ones are right for you will depend on the product type, its function and the environment in which it will be used.

Explore the services that Procision Manufacturing offers for the medical industry.

Injection molding is the most popular choice for producing plastic medical parts. It is efficient for large-scale manufacturing.

We offer tooling and injection molding in both general-use and specialty medical-grade resins, including POM, PEEK, Ultem, and more. Additionally, we provide medical micro molding services able to produce small components with exceptional precision.

Vacuum casting is one of the best methods for making high-fidelity, production-quality medical prototypes. It requires minimal tooling costs, offers a fast turnaround, and produces finished parts with excellent surface texture.

They are well-suited for proof-of-concept models, and can support engineering testing, benchmarking, design iterations, and more.

CNC machining is highly scalable and has no minimum production requirements, making it useful for prototyping and custom parts manufacturing.

It can fabricate many medical materials to close tolerances, such as titanium, aluminum, stainless steel, and engineering-grade plastics.

Product Design Support

Before production begins, you’ll receive a Design for Manufacturing (DFM) review which can lower costs and shorten lead times.

Positive Material Identification

All incoming raw materials used in your custom medical products will be identified using sophisticated metrology equipment so it meets your stringent regulatory and safety requirements.

Rigorous Quality Control

Procision inspects your parts at every step of production. Our practices include first article, in-process, and final inspections.

Comprehensive Manufacturing Solutions

Our turnkey services cover all of the fundamental processes needed to turn plastic and metal raw materials into outstanding medical finished parts.

Tight Tolerances

Medical device manufacturing is performed with digital equipment operated with advanced software for the highest degree of accuracy and repeatability.

A Full Suite of Finishing Services

It’s impossible to pinpoint the “best” method, as it largely depends on the device type, its specifications, size, production volume, materials used, and other factors.

In general, medical prototyping can be done using CNC machining or vacuum casting. For plastic components made in higher volumes, injection molding is the most popular option.

Defining the best material for your project is challenging, as no single solution fits all types of products. This choice depends on budget, the product’s intended application, and the environment in which the part will be used, among other factors.

It’s a complex decision, but if you place an order, our engineering team will help you make an informed choice.

Costs vary significantly depending on the type of product. Factors influencing the final price include the material used, the selected manufacturing method, production volume, and tooling requirements.

Procision Manufacturing has no minimum order values or volume restrictions and provides custom quotes tailored to your production needs.