Procision Manufacturing

Prototype to Production Metal & Plastic Parts

The world of automotive parts manufacturing relies on successfully integrating thousands of discrete components into a finished product that must function reliably for years under hard use. A very widely distributed supply chain must therefore adhere to strict quality guidelines that guarantee compliance with raw material specifications and tight physical tolerances.

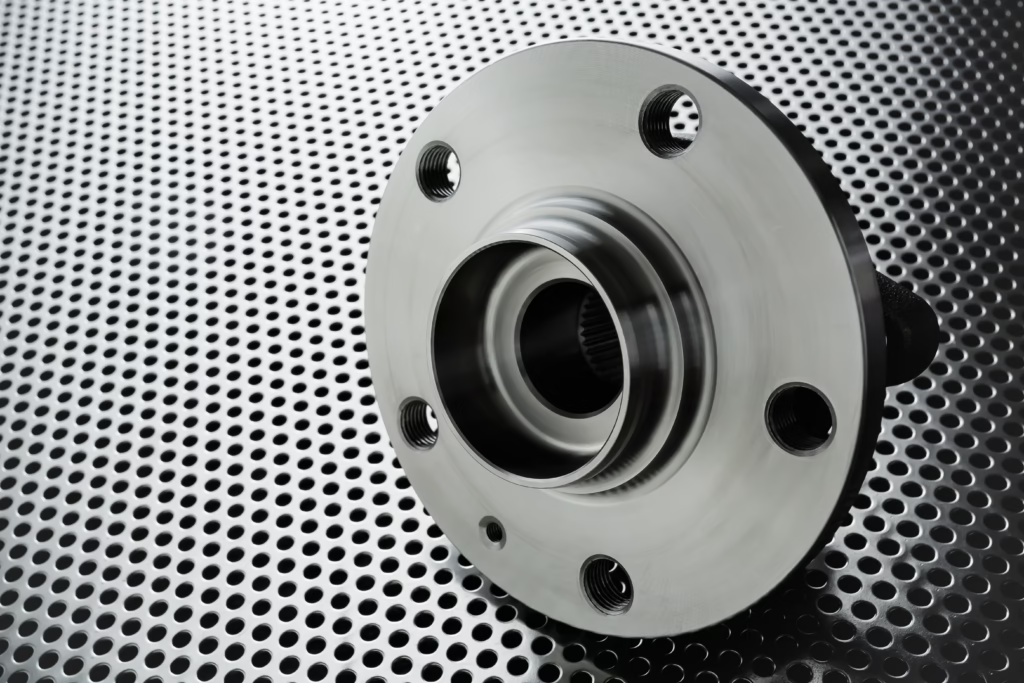

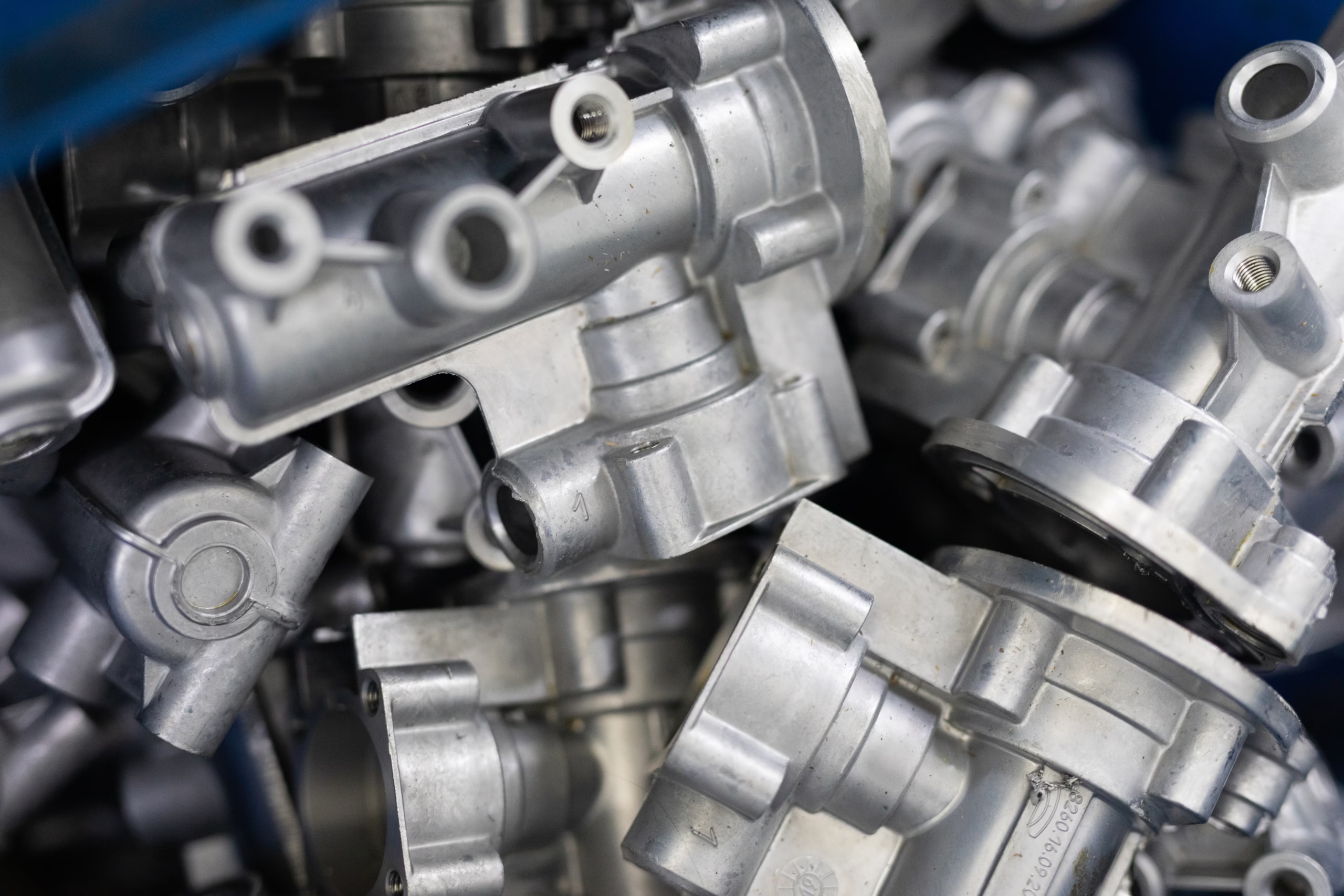

Procision Manufacturing meets this challenge, delivering high-quality parts at the lowest possible cost thanks to our engineering support, advanced machinery, and rigorous quality inspections. We have under one roof CNC milling and turning, plastic injection molding and micro molding, high-pressure die casting and a full line of post-manufacturing finishing options to perfect your custom automotive part designs.

Scalable Production

Our services are flexible in scope, ranging from custom one-off prototypes to millions of identical parts. You get exactly the number of parts you need.

Cutting-Edge Technology

We provide a combination of multi-axis CNC turning and milling centers, fully electric conventional and micro injection molding machines, high pressure die casting machines.

Material Expertise

Metals include aluminum, magnesium, zinc, mild and stainless steels, titanium, Inconel, and brass. We also have a standard stock list of hundreds of plastic resins.

Uncompromising Quality

Strict quality control is maintained with careful material verification of incoming materials through to final inspection and shipping – all backed up with full test reports for complete transparency.

Expert Engineering Support

We help you optimize your designs, find efficient solutions, and handle everything related to turning your parts into reality.

Fast Turnarounds

Our streamlined production planning and efficient logistics minimize lead times while our dedicated project managers keep you updated at every step.

We provide a full range of services and will work with you to determine which are best suited for your next project.

With vacuum casting, you can obtain production-quality prototypes in just a few days. The process involves creating a master model, which is precisely replicated in urethane resins using silicone molds.

Yes, we are confident that we can manufacture your parts to your exact specifications. We also provide all the necessary documentation for compliance and supply chain traceability.

Procision can’t create design files or models for you, but we can refine the ones you already have. Every project includes a Design for Manufacturing review, where we assess tolerances, material selection, feature feasibility, and tooling requirements. This ensures better designs that are easier and more cost-effective to produce.

We work with materials commonly found in the automotive industry, including mild and stainless steel, aluminum alloys, magnesium, zinc, titanium, Inconel and brass, as well as hundreds of thermoplastics and composites such as carbon fiber. If you need specialty materials, feel free to speak with our engineering team.

Tolerances depend on many factors, such as materials and manufacturing methods, but in general, we comply with the following:

Lead times depend on part complexity, material selection, and production volume. Prototypes can be made in a few days, rapid tools can be ready in as little as 10 days, and complex CNC machined or die-cast parts can take weeks.

Before we start our partnership, our team will clearly explain lead times to you and update you about the schedule.

Pricing depends on material selection, tooling requirements, production volume, post-processing needs, and more. Beyond that, we believe in a personalized approach for each project, making it impossible to predict costs upfront.

However, once you share your part details with us, we’ll provide a quote with transparent pricing so you know exactly what to expect.

Yes. We can hold mold tools in storage for up to five years so you can reorder and receive your parts fast, every time. You can also request minor adjustments or redesigns.