From Prototyping To Mass Production

Surface Finishing Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Procision Surface Finishing Services

Surface Treatment For Your Parts

The right surface finish can improve the performance and appeal of your parts in many ways.

Whether you need increased wear resistance, better corrosion protection, or a flawless appearance, Procision’s services ensure your products will look and perform just as you expect.

We offer multiple options available in-house or under our direct supervision. Choose plating, anodizing, painting, polishing, laser etching, and many more.

Procision Surface Finishing Services

Surface Finish Options

Different treatments yield different results, such as refined surface textures or specific cosmetic effects . Our primary services include:

- Anodizing

- Painting

- Pad and Silk Screen Printing

- Laser Etching

- Sanding and Polishing

- Vapor Polishing

- Media Blasting

Procision Manufacturing

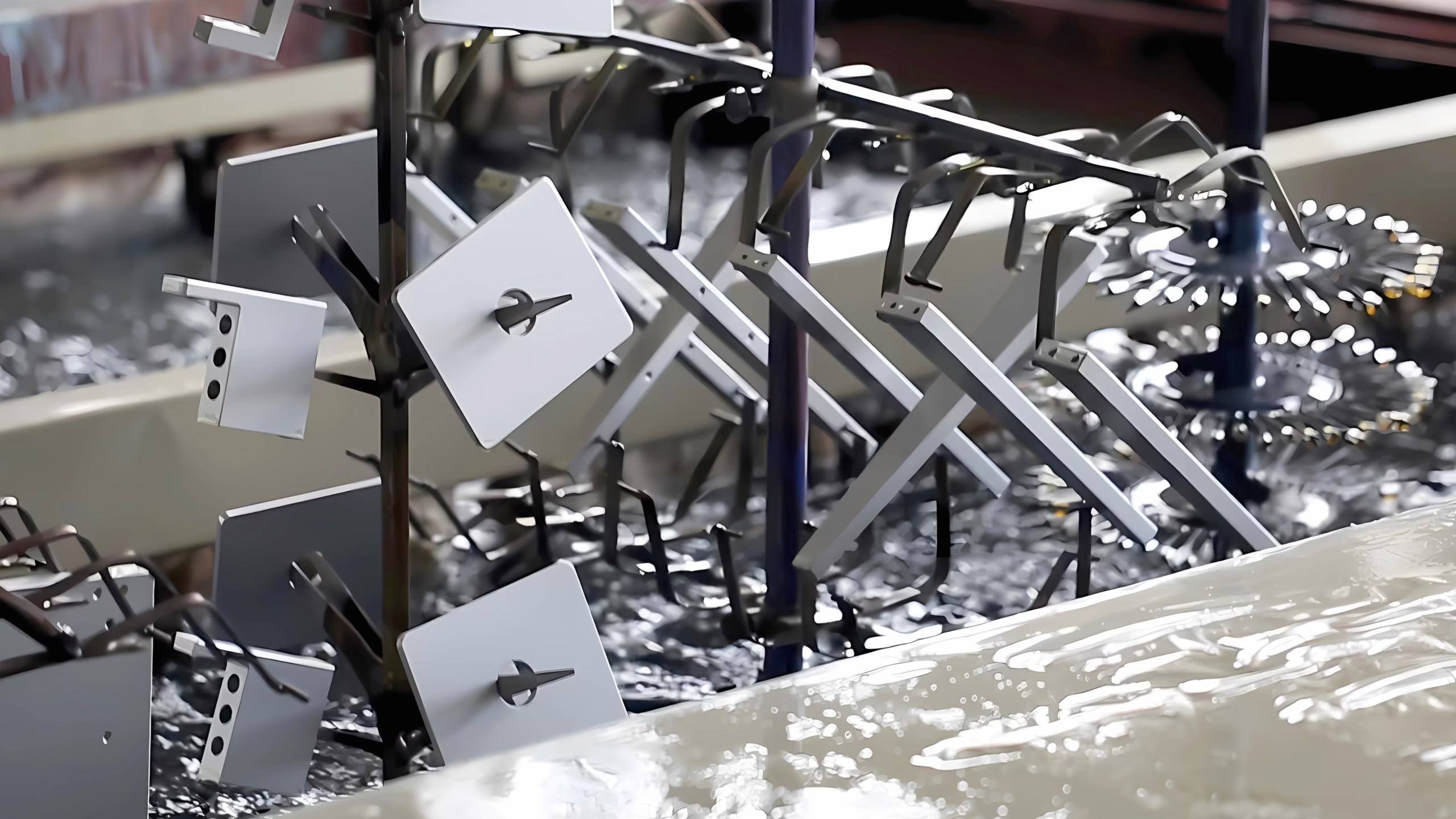

Anodizing

Anodizing creates a protective oxide layer on some metal surfaces. It increases corrosion resistance, surface hardness, and wear resistance while providing a unique look to the parts.

Our standard service is type II anodizing, which can be color-customized. Type III anodizing is also available for surfaces that need to be extra hard.

How it is done: The part is cleaned to remove oils and contaminants, then submerged in a sulfuric acid bath. An electric current is applied to form a porous oxide layer. If coloring is required, electrolytic or dip coloring is used. Then, the part is sealed in boiling deionized water and blow-dried.

Applications: Aluminum, magnesium, and titanium accept anodizing the best.

Procision

Painting

A good paint job is one of the best ways to make your product stand out. Many colors and surfaces can be achieved, such as matte, flat, gloss, and semi-gloss.

Procision uses 6-axis painting robots for fast turnaround and consistent results.

How it works: Painting is done in climate-controlled spray rooms. The part is first cleaned and prepared, and then PPG automotive polyurethane paints are used to replicate your desired color, tint, or hue. Parts are dried in infrared ovens for the best results, and then sent to our quality inspection department for color matching tests.

Applications: Most materials can be painted, including plastics, metals, and composites. However, some specialized resins like PTFE are difficult to paint without extensive preparation.

Procision

Pad Printing

Pad printing is one of the best methods for adding logos, labels, and detailed graphics to a flat or slightly curved surface. It is fast and inexpensive, but is limited to one color at a time.

How it works: A rubber pad picks up ink from an etched printing plate and transfers it onto the part’s surface. The stamp’s flexibility allows it to conform to curved shapes.

Applications: Pad printing is compatible with many plastics, metals, and coated surfaces. In addition to branding, it can be used to mark part numbers, serial codes, and other identifying information.

Procision

Laser Etching

Laser etching is an even more durable marking technique that can be applied to flat surfaces. It doesn’t add color, but is more precise and provides finer resolution and detail than other methods.

How it works: A low-power laser is used to burn away a minute amount of surface material in a controlled pattern, revealing the base material in contrast to the surrounding area.

Applications: This process can be used to add company logos and graphics, serial numbers, QR codes, manufacturing data, and other information. Etched surfaces won’t fade over time and can’t be accidentally wiped off, so they’re useful for products that might be exposed to adverse environments.

Ready For Start Your Project?

Are team of technical professionals are ready to assist.

Procision

Silk Screening

And what if you need to apply complex, multi-colored designs? Then silk screening is the answer.

How it is done: A fine mesh screen is stretched over a frame. Paint is squeezed through it, using a stencil to define the design. Several screens and stencils are used in series for more sophisticated images or patterns.

Applications: It can be applied to most hard, flat surfaces that require detailed graphics or markings. It is commonly used on plastic, metals, and coated parts.

Sanding And Polishing

Sanding and polishing are applied as preparation for other services, to remove burrs, or to achieve smooth surface effects.

How it works: Sanding relies on abrasives of varying grits, while polishing uses fine powder, rouge or paste. Depending on the application, sanding and polishing is performed by hand or with rotary buffing tools.

Applications: It’s ideal for plastics, metals, and composite materials where surface smoothness impacts function or appearance.

Procision

Vapor Polishing

Vapor polishing is a specialized finishing process for making optically clear plastic parts.

How it works: First, the part is sanded, usually between 1000 and 1500 grit. Then, Weldon 4 solvent is heated to the boiling point in a controlled environment. The resulting vapors are sprayed onto the workpiece, causing it to melt and flow at the microscopic level which evens out any minor imperfections.

Applications: It is used mainly to create clear polycarbonate (PC) parts. Other plastics like PMMA also accept this finishing well, though it typically has good transparency right after molding.

Procision

Blasting

Blasting treatments are used to remove minor surface imperfections, clean contaminants, and create specific surface textures.

How it works: High-pressure guns are used to spray abrasive media onto the workpiece. Sand, glass beads, walnut shells, garnet, or even pure water can be used. The media impacts with the workpiece, removing rust, contaminants, and small marks while imparting unique and subtle effects to the surface.

Applications: Most metal and some kinds of hard engineering plastics can be media blasted. In virtually all cases, the result is a uniform matte or non-reflective surface without any noticeable orientation or pattern.

Depending on the abrasive media and technique utilized, it can also improve adhesion for the later application of paint or primer.