Excellence Without Compromise

CNC Turning Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

How To Work With Us

Step 1

Upload Design

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Quote & DFM

Step 3

Manufacturing

Step 4

Shipping

Procision Manufacturing

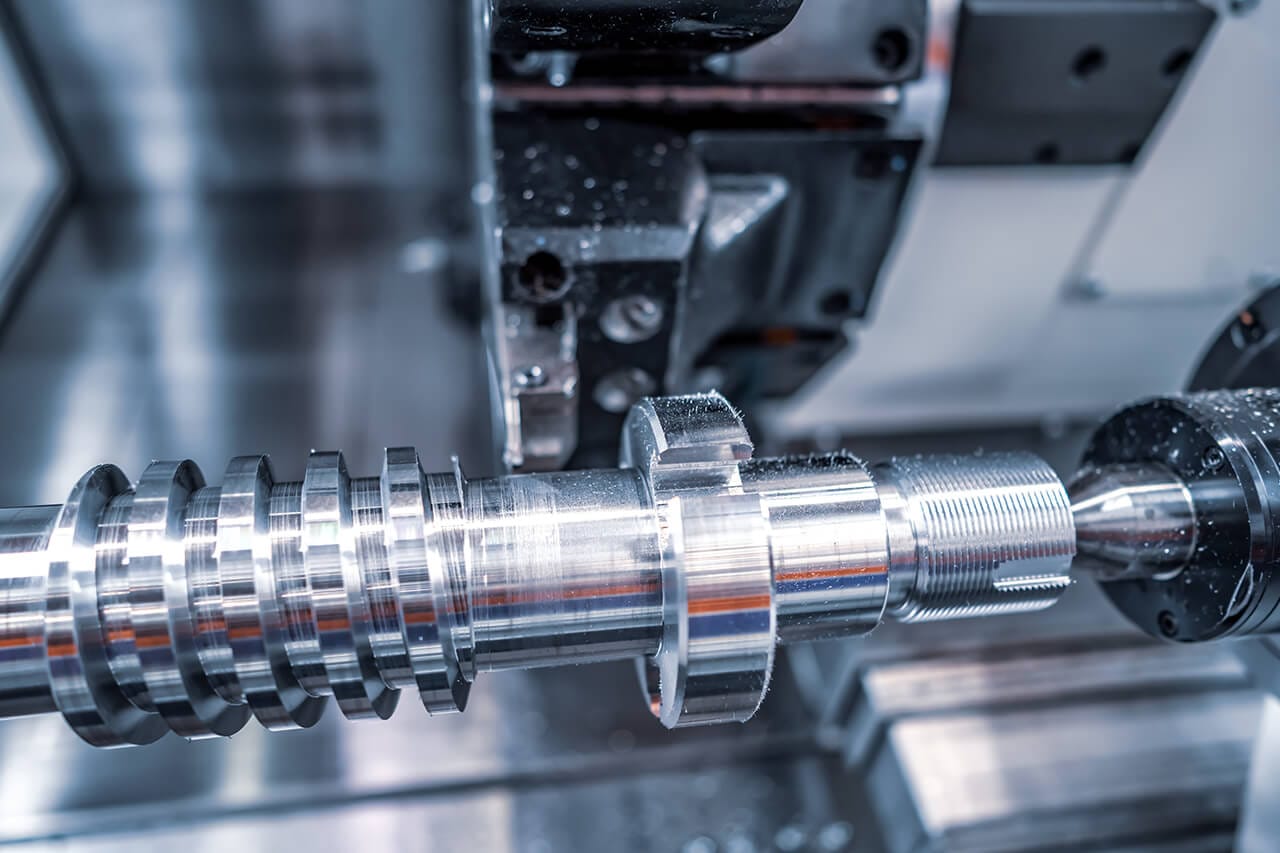

Expert CNC Turning Services

Are you tired of dealing with inconsistent quality, unreliable suppliers, or slow delivery times? At Procision Manufacturing, we specialize in solving these challenges with expert CNC turning services tailored to meet your exact requirements.

Advanced CNC turning centers and Swiss lathes, paired with premium imported cutting tools in a climate-controlled workshop, ensure precise and durable parts with superior surface finishes. Every component is rigorously inspected at multiple stages of production to meet your specifications.

Whether you need a single prototype or a full production run, you can expect quality custom parts with speed, reliability, and accuracy.

CNC TURNING

Why Choose CNC Turning?

CNC turning is known for its efficiency in removing material quickly. Using high-quality cutting tools achieves a smooth surface finish without requiring post-processing. This method is ideal for manufacturing:

- Internal and external threads

- Ring grooves

- Tapers

- Long bores

- Other intricate round features

With advanced live tooling capabilities, CNC turning is optimized for speed and precision in creating cylindrical parts — saving time and reducing production complexity.

Why Choose Us?

CNC Turning Services — Why Work With Procision?

Working with Procision Manufacturing means more than just receiving precision-turned parts — we are your reliable manufacturing partner dedicated to resolving common frustrations like poor quality, unreliable suppliers, and inconsistent delivery times. Here is why our partners work with us:

Consistent Quality

Tired of unpredictable quality? Our CNC turning services combine the finest equipment and materials under strict quality control to ensure.

Global Standards

Burned too many times by unreliable suppliers? We ensure consistent performance, strict quality control, and environmentally responsible solutions.

Fast Turnaround

Worried about missed deadlines? Our digital systems rely on advanced software to reduce production time without

Material Assurance

Concerned about mismatched or subpar materials? Our Positive Material Identification (PMI) guarantees that all raw materials are subject to strict quality control and testing to meet your exact

Need High-Precision CNC Turning Parts?

We are a team of technical professionals ready to assist you.

Common Questions

CNC Turning Service FAQ

Find answers to common questions about CNC turning services and why industries like medical, electronic, agriculture, and consumer products trust Procision to achieve their production goals.

What are CNC turning services?

CNC turning is the most accurate and close tolerance method for quickly removing material from round and cylindrical stock.

This method is ideal for creating high-precision cylindrical parts such as shafts, bushings, and intricate threaded components across a wide range of materials including metals, plastics, and composites.

Our skilled machinists deliver exceptional versatility, accommodating everything from accurate prototype parts to large-scale production runs of metal and plastic components.

What are the advantages of CNC turning?

CNC turning offers accuracy, repeatability, and consistency. It’s ideal for creating complex geometries and intricate features like threads, holes, and grooves. Additionally, CNC turning allows for fast production times and minimal human intervention, reducing the chances of errors and enhancing part quality.

What types of materials can be used in CNC turning?

CNC turning can accommodate a wide range of materials, including metals and plastics. While most solid, stable materials can be turned, extremely hard tool steels may necessitate specialized treatments or longer production times. Similarly, soft elastomers and certain plastics may be unsuitable due to their inability to maintain a fixed position or resist deformation under cutting pressures.

What is the typical lead time for CNC turning services?

The lead time for CNC turning can vary based on the complexity of the part, material selection, and quantity. Our advanced CNC turning machines and automation provide a fast turnaround.

What is the difference between CNC turning and CNC milling?

CNC turning uses a rotating workpiece and a stationary cutting tool, which is ideal for producing cylindrical parts. CNC milling, on the other hand, uses a stationary workpiece and a rotating tool to cut complex shapes, such as prismatic components or intricate geometries. While turning is perfect for round parts, milling is better for flat or angular parts.

What industries use CNC turning?

CNC turning is widely used across various industries, including aerospace, automotive, medical devices, electronics, and consumer products. It’s ideal for producing components with tight tolerances, such as gears, fittings, valves, and connectors, where consistency and accuracy are critical.

How is CNC turning different from traditional turning?

Traditional turning involves manual operation or semi-automatic machines, where the operator controls the tool position. CNC turning, however, is fully automated, using computer programs to control the tool paths. This results in higher accuracy and precision, faster production times, and the ability to create more complex geometries with minimal human intervention.

How much does CNC turning cost?

The cost of CNC turning depends on several factors, including material selection, part complexity, machine time, and quantity. We are committed to competitive and cost-effective pricing — whether you need relatively simple, small parts or complex, large parts that require more machining time. Submit project details and an optional CAD file and experienced engineers will determine an accurate quote for your project.

How do I get CNC turning services?

Getting started with CNC turning services is easy. Simply request a personalized quote, and experienced specialists will guide you through every step of the manufacturing process — from initial design to final production and delivery. Let us ensure your project’s success with expert support at every stage.

Start Your CNC Turning Project Today

Don’t settle for less. Get precision, reliability, and speed with Procision’s CNC turning services. Submit your design for a free quotation and let’s bring your custom parts to life.