From Prototyping To Mass Production

Prototyping and Tooling Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

- British, Danish & South African Owned

- ISO9001 & ISO13485 Certified

- Full DFM & Global Technical Support

- No MOQ/MOV & Exceptional Customer Satisfaction

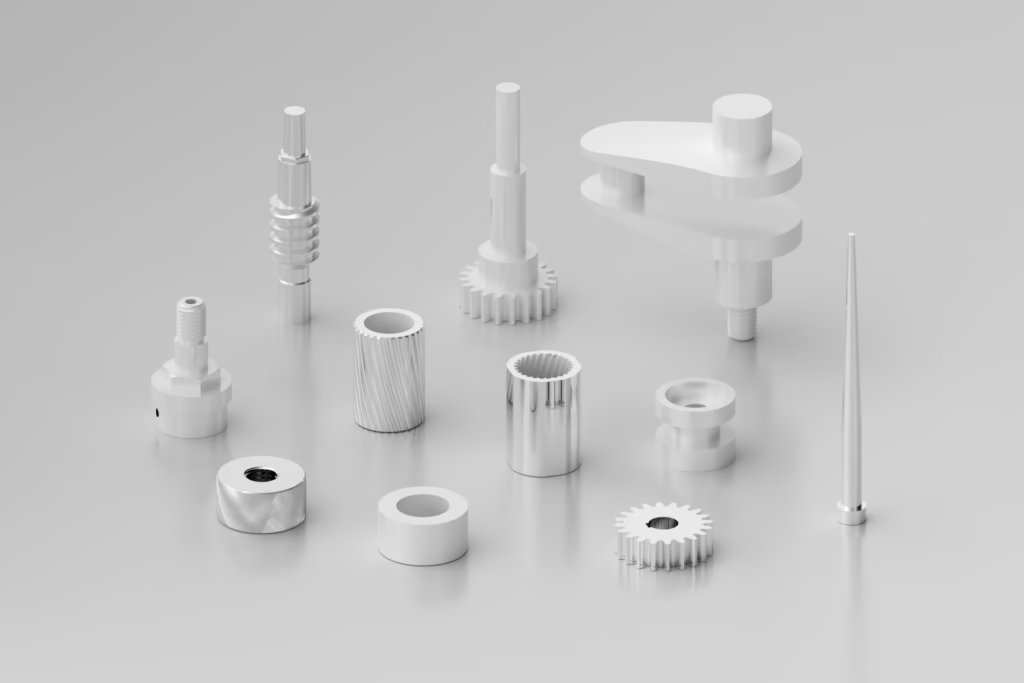

Procision Rapid Prototyping

Rapid Prototyping For Any Industry

Launching a new product is challenging, and design files don’t always reveal all the flaws or opportunities for improvement. Skipping straight to mass production increases your financial risks, and can waste precious time and money.

That’s why companies use rapid prototyping to help them get products to market while controlling their financial exposure.

Procision offers CNC machining, vacuum casting, and rapid tooling services to support your needs for custom parts fast – so you can iterate, validate, and launch on time.

Procision Rapid Tooling

Rapid Tooling For Any Industry

How it works

Varieties of Prototypes

Prototypes serve many different purposes and these will then directly determine the best tools used to make them.

Visual Prototypes

To visualize a product’s shape, size, and overall appearance. Usually made from simple materials, like clay, foam, paper, or 3D printing filament.

Proof-of-concept Prototypes

To test whether an idea is feasible in early-stage design development. They use basic materials and quick manufacturing methods.

Test The Market

Test the market with your product before production

Functional Prototypes

Replicating final part properties for performance testing and material validation, using advanced materials and precision techniques like CNC milling.

Pre-production prototypes

Used for final validation with production-grade materials and methods to detect issues before mass manufacturing and to aid with regulatory approvals.

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

Common Questions

Procision Prototyping and Tooling Service FAQ

How are prototypes made?

There is no single answer to this question, as the process can vary from project to project. The best fabrication method depends on the prototype’s purpose, material requirements, budget constraints, and other factors.

What are the most common processes for rapid prototyping?

At Procision, we make prototypes using CNC machining and vacuum casting, while rapid tooling is ideal for limited production volumes of simple geometries using standard resins.

How much does rapid prototyping cost?

It’s impossible to anticipate the price of a prototype. Chosen process, material type, part complexity, prototype function, and production volume are all driving costs that must be considered.

How does Procision ensure the prototypes will faithfully replicate the finished product?

When making functional prototypes, it is important to select the right manufacturing methods, materials, and surface finish treatments, and to perform quality inspection to guarantee that the prototype is accurate. Procision has fully equipped CNC machining, injection molding, finishing, and quality control departments to handle all such tasks.

Why Choose Us?

Whether you’re testing concepts, refining performance, launching a new product, or making a bridge to volume production, Procision has everything needed to keep your project moving forward fast.

We understand the importance of high-quality prototypes and tools, and we have the capabilities to manufacture custom, precise, low-volume parts with exceptional fit and finish.

Advanced Equipment

Our facility is equipped with multi axis CNC mills and turning centers, sink and wire EDM, injection and micro injection molding machines and a dedicated vacuum casting department.

Short Lead Times

Time is critical for product development, so we prioritize fast turnarounds. We follow a lean manufacturing philosophy, use cost-efficient prototyping techniques, and can effectively balance speed, cost, and quality.

Material Versatility

Our proprietary AI quoting algorithm ensures you receive fast and accurate quotations to help you reach your product development goals while managing your budget.