From Pilot To Production Scale

Reliable, Scalable Mid-Volume Manufacturing Services

-

British, Danish & South African

Owned

-

ISO9001 & ISO13485

Certified

-

Full DFM & Global Technical

Support

-

No MOQ/MOV & Exceptional

Customer Satisfaction

Step 1

Upload Design

Begin your project by selecting a manufacturing process and uploading your design file.

Step 2

Quote & DFM

Step 3

Manufacturing

Step 4

Shipping

- Total Projects

For more than 10 industries

- CNC Machines

Imported multi-axis

- CNC Materials

To choose from

- Service Satisfaction

Based on yearly surveys

Procision Low-Volume Manufacturing

The Flexible, Cost-Effective Bridge Between Prototype and Mass Production

No Arbitrary MOQs

Procision doesn’t have minimum order quantity requirements. Whether you need hundreds or tens of thousands of parts, our flexible manufacturing system scales to fit your needs—without sacrificing speed, precision, or consistency.

Optimized for Repeatability and Throughput

Mid-volume manufacturing demands consistency. We use process controls, in-line inspection, and stable tooling strategies to keep each batch within spec, all backed up with ISO quality certifications.

Procision Low-Volume Manufacturing

Proven Partnership. Reliable Output.

Clear Communication Across Every Phase

Our project managers work as part of your team—ensuring proactive updates, fast approvals, and alignment on lead times and technical details. No surprises.

Scalable Support from Start to Finish

From Design for Manufacturability review and material selection through to packing and global shipping, Procision supports your production lifecycle with engineering prowess and accountability at every step.

Mid-Volume Manufacturing Capabilities

Plastic Injection Molding

Our mid-volume plastic injection molding solutions are ideal for producing custom, mid-volume components with rapid tooling and versatile resin options. We specialize in bridging the gap between prototype and plastic part production with cost-effective molds, insert molding, and material guidance to ensure function and durability.

- Low-cost tooling tailored for 500–10,000 unit runs

- Engineering support for mold flow and design validation

- Optional overmolding, multi-shot, and part serialization

Low-cost tooling tailored for 500–10,000 unit runs

Engineering support for mold flow and design validation

Optional overmolding, multi-shot, and part serialization

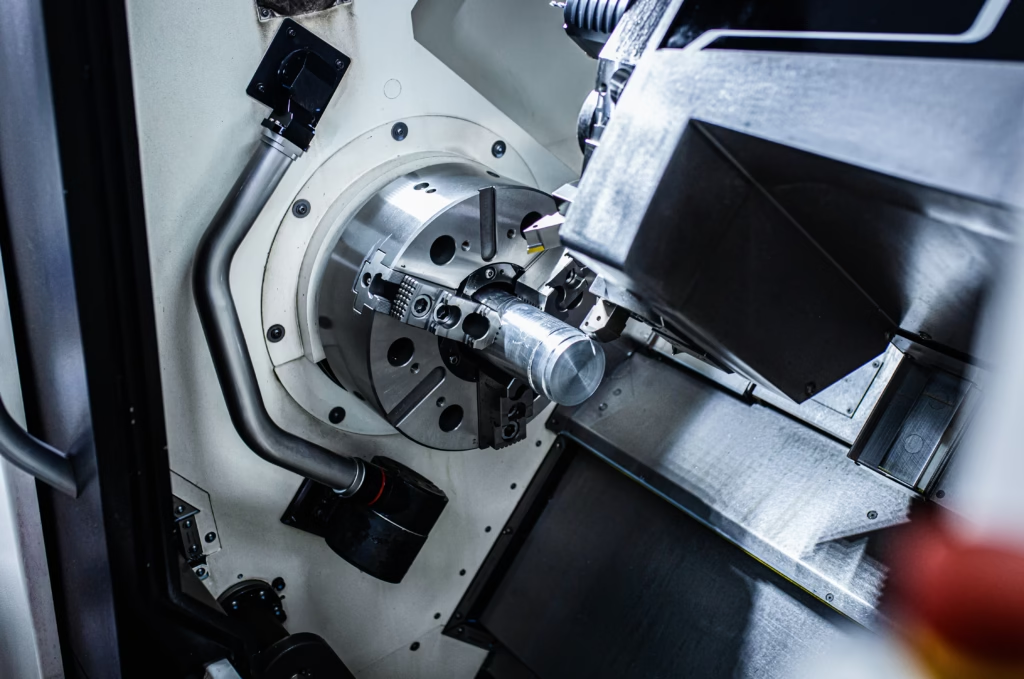

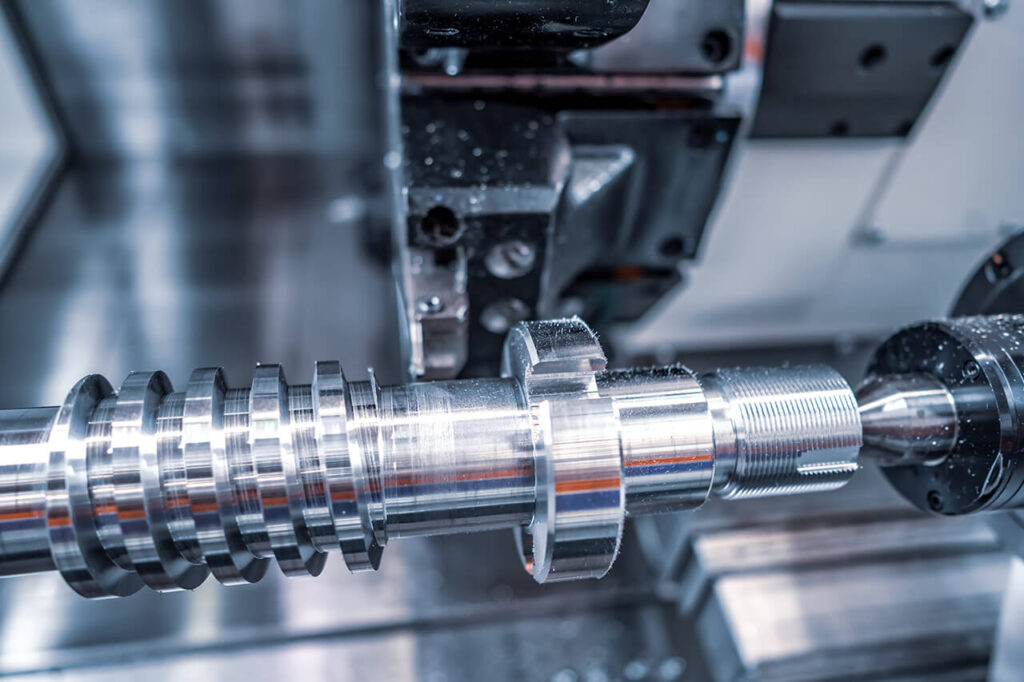

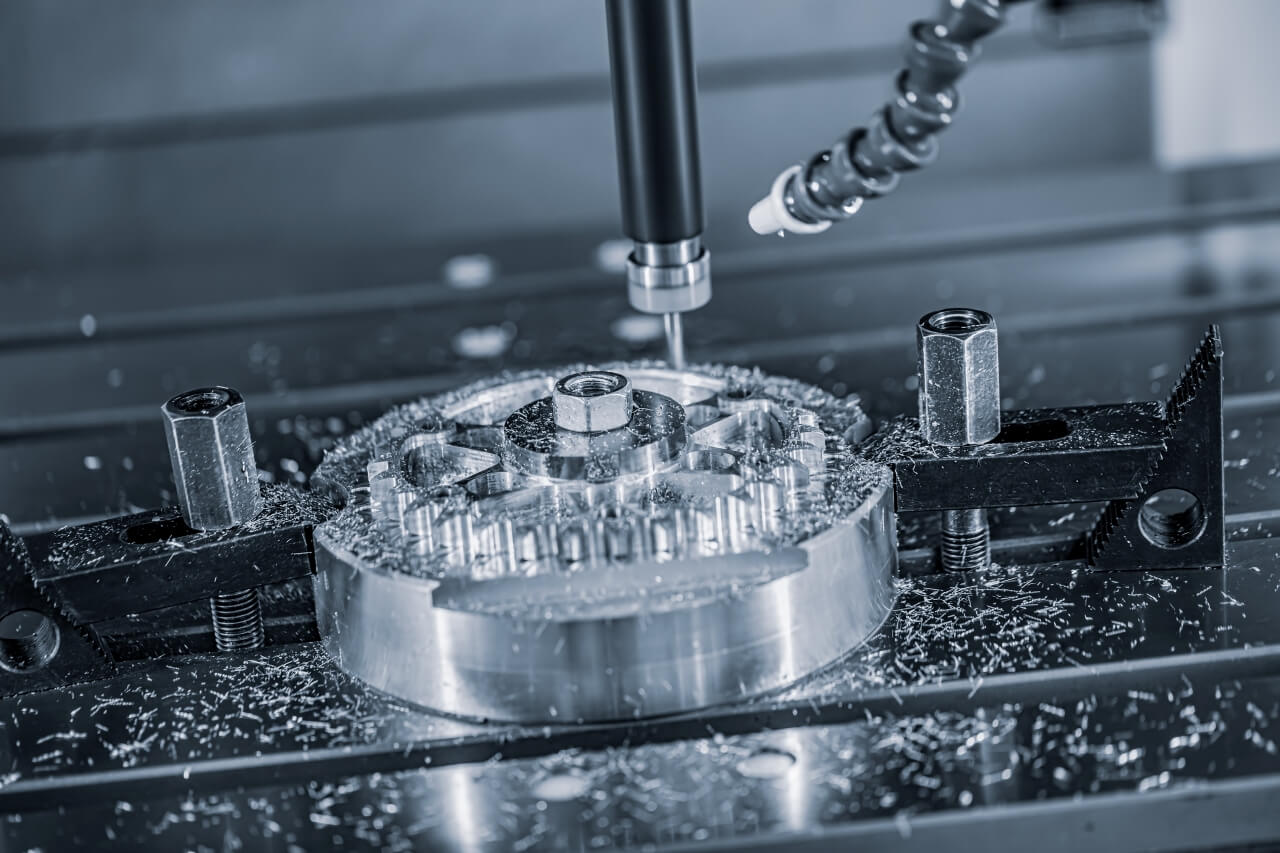

CNC Machining

Leverage CNC machining for complex geometries and tight tolerances across aluminum, steel, and engineering plastics. Our agile setups and flexible fixturing enable repeatable, production-grade parts without the burden of high-volume tooling. Whether you’re producing 250 or 2,500 units, we deliver consistent, high-quality results with optimized cycle times.

Precision tolerances and scalable production

High-mix part capability with setup efficiency

In-line inspections for quality at every step

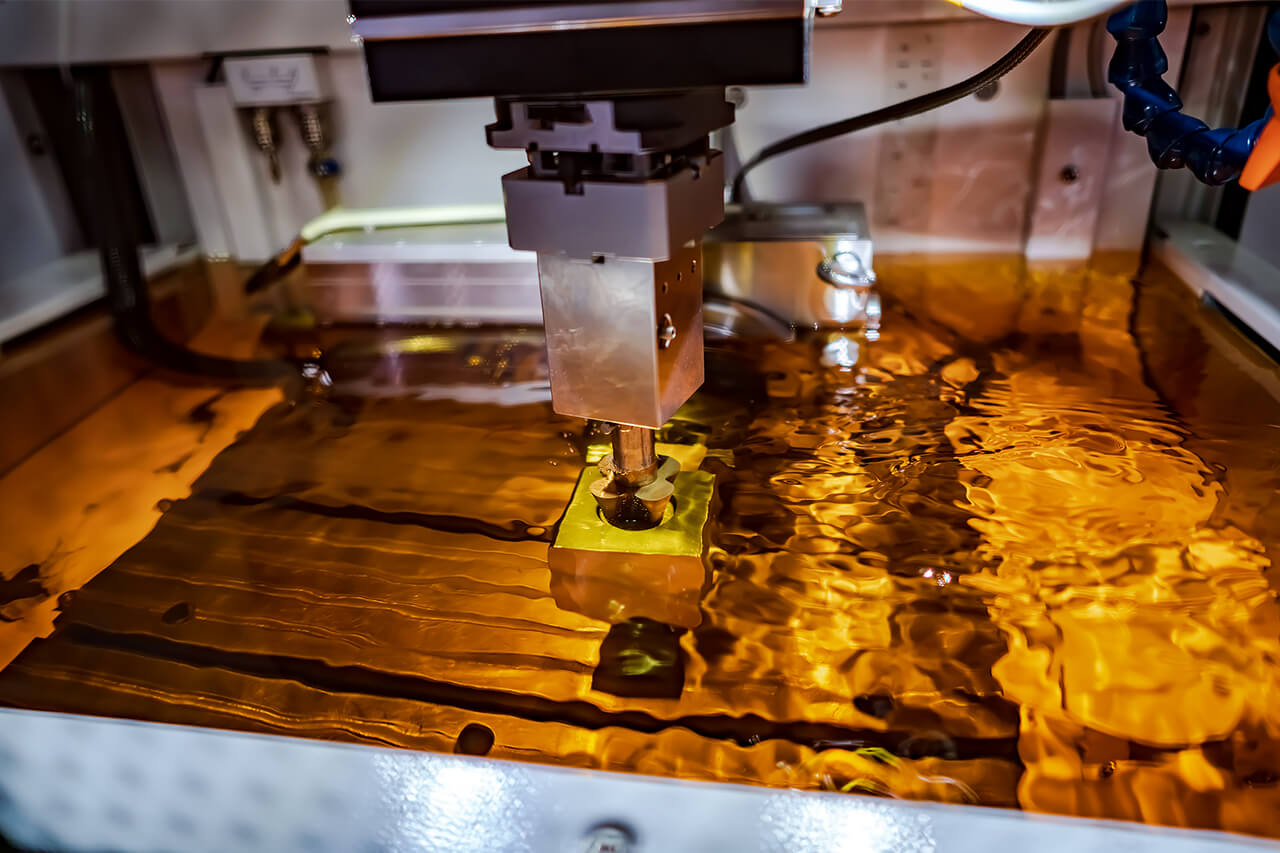

EDM Services

Machine intricate cavities in hardened steel featuring sharp right angles using electrical discharge machining (EDM). Ideal for mold making and specialty tooling — no post-processing required.

Surface Grinding

Ensure exceptional flatness and various finishes for your CNC parts. Using controlled abrasive wheels, surface grinding offers the accuracy you need for smooth, consistent results.

Rapid Tooling Services

Accelerate your product development. Our rapid tooling capabilities deliver fast, accurate mold tooling for injection molded parts — perfect for low-volume production and iterative prototyping.

Why Choose Us?

Why Partner with Procision Manufacturing?

Procision helps hardware developers, OEMs, and product teams manage production-scale needs with control and confidence. Here’s what sets us apart:

DFM Built Into Every Program

Design For Manufacturability isn’t a line item—it’s our standard. We identify geometry and tolerance optimizations that can improve manufacturability, lower cost, enhance quality, and shorten lead times at mid-volume scale.

Material Validation & Lot Traceability

Every material batch is tested for compliance and backed with traceability and compliance documentation. You’ll know exactly what your parts are made of—and that they’ll perform as specified.

Repeatable, Documented Quality Control

We implement rigorous inspection protocols across every mid-volume production run. From dimensional accuracy to cosmetic finish, we ensure each part meets your critical tolerances and visual specs.

Human-Driven Quotations

No instant quoting bots. Your custom design files are reviewed by an engineer who understands your goals—and flags risks, cost drivers, or DFM opportunities that an algorithm would miss.

Efficient Global Logistics

From packaging to customs, our logistics workflows are built for reliable production batch delivery. We’ll help you meet product launch windows and avoid bottlenecks.

Ready To Start Your Project?

Are team of technical professionals are ready to assist.

- Unmatched Accuracy – Produce complex geometries with extreme precision

- Material Versatility – Metals, plastics, and advanced composites

- Speed & Efficiency – Minimize tooling investment while maximizing throughput

- Consistency at Scale – Seamless transition from prototype to production

- Superior Surface Quality – Eliminate the need for secondary processing

- No Volume Limits – Flexible support for small batches or large production runs

When you need consistent performance — and zero compromise — trust Procision’s CNC machining services to deliver.

Confidentiality You Can Count On

Common Questions

Mid-Volume Manufacturing FAQ

Find answers to common questions about CNC machining services and how industries like medical, electronic, agriculture, and consumer products can achieve their goals by working with Procision.

What volumes qualify as “mid-volume”?

Mid-volume manufacturing can range from 10K~100K per year, as opposed to a few thousand for low-volume manufacturing and millions for full production.

What industries do you serve?

We work with clients in medical, consumer, industrial, aerospace, and clean tech markets—especially where quality and traceability are non-negotiable.

How do you ensure repeatability over multiple runs?

We maintain documented process controls, tooling condition monitoring, and in-line QC checks to deliver consistent results from run to run. Our entire manufacturing production area is climate-controlled 24/7 to ensure material stability and consistency.

Can I order in batches or staged releases?

Yes. We support kanban, buffer stock, and staggered delivery programs so you can align inventory with demand—without overcommitting capital.

Do you help with production transition planning?

Absolutely. We’ll help you bridge from prototype to mid-volume and beyond, coordinating manufacturing production, tooling upgrades, and documentation as volumes increase.

Ready To Scale Up with Confidence?

Whether you’re building one part or one million, the Procision team delivers consistent results — on time, to spec, and built to perform. Request a quote today and discover what a responsive, professional CNC machining manufacturer can do for you.