Procision Manufacturing

Prototype to Production Metal & Plastic Parts

Creativity and great design are just the starting point for innovation in the consumer goods market.

The key to making a successful consumer product is transforming technical drawings into consistently high quality parts that deliver the appearance, functionality and feel that consumers expect. No matter how specialized your focus may be, Procision has the expertise and technical capabilities to bring new custom products to market fast.

We offer CNC machining, plastic injection molding, high-pressure die casting, vacuum casting, end-to-end technical inspections, and surface finishing services.

These capabilities support every stage of your production. We provide consumer product prototyping to validate your concept, low volume manufacturing to build your brand while you test the market, and full-scale manufacturing with consistent quality.

Industry Expertise

We are manufacturing veterans in a wide range of disciplines and industries.

Manufacturing Versatility

With CNC machining, plastic injection molding, vacuum casting, and high-pressure die casting, we’ve got you covered.

Surface Finishing Options

We can enhance your product’s appearance and performance through various surface finishes.

Design Optimization

Our team will perform a Design For Manufacturing (DFM) review to optimize your part design for the chosen materials and production methods.

Quality Assurance And Control

We start with positive material identification (PMI) of all raw stock, and continue with in-process and final inspections using advanced digital metrology equipment.

Transparent Communication

You will always have an open communication channel with our team to clarify any questions, track progress, and follow the schedule of your parts.

Various manufacturing processes are pivotal in the consumer goods industry. Here is an overview of the methods Procision specializes in.

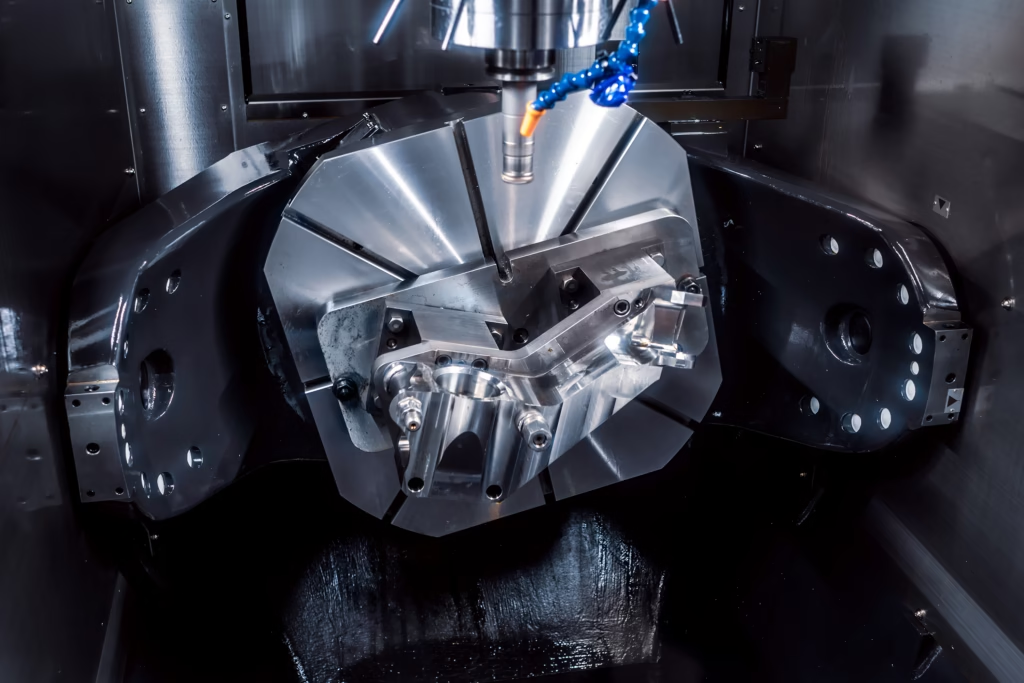

CNC machining uses digital controls to selectively remove material from the workpiece from multiple angles. It is widely used in consumer products to manufacture complex metal and plastic components.

Procision offers CNC turning, CNC milling, and EDM machining services.

The best way to make unlimited volumes of identical plastic parts at the lowest cost. We provide rapid and production tools as well as finished parts in hundreds of stock resins.

Our machine capacities range from 10 to 1000 tons to suit any project size.

With vacuum casting, you can obtain production-quality prototypes in just a few days. The process involves creating a master model, which is precisely replicated in urethane resins using silicone molds.

Procision handles the casting and manufactures dies in tough, semi-hardened tool steels that can withstand many thousands of cycles. High pressure die casting offers:

Our team can help you optimize designs, select the best materials and manufacturing methods, verify raw materials, fabricate the designs to a high standard, apply the necessary surface finishes, inspect the parts, perform light assembly if needed, and deliver them anywhere in the world.

Factors influencing your decisions include product functionality, cost, aesthetics, durability, and production volume. There may in fact be more than one solution, which is why our team can work with yours to find the best alternatives.

We perform Positive Material Identification (PMI) for every order to ensure that your raw materials meet your exact specifications to help you achieve your performance and regulatory compliance goals.

In addition, we conduct in-process inspections, First Article Inspection (FAI), and final inspections. All tests are documented, and data is shared with your team whenever required.

Overmolding means molding one type of plastic resin on top of another dissimilar one. Typically, a soft material like rubber or thermoplastic elastomer (TPE) is molded over a rigid plastic to enhance grip, protect internal components, shield against heat, shock or moisture, and to impart a company’s logo.